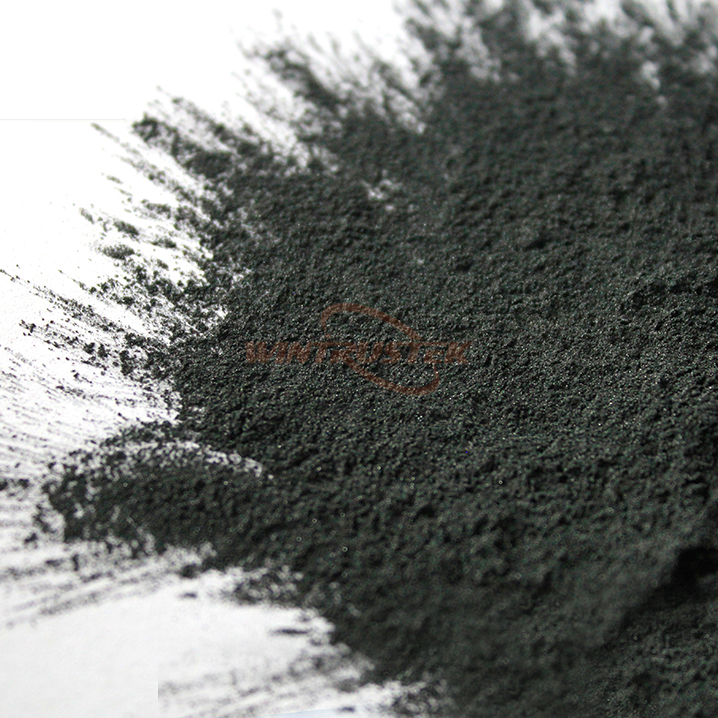

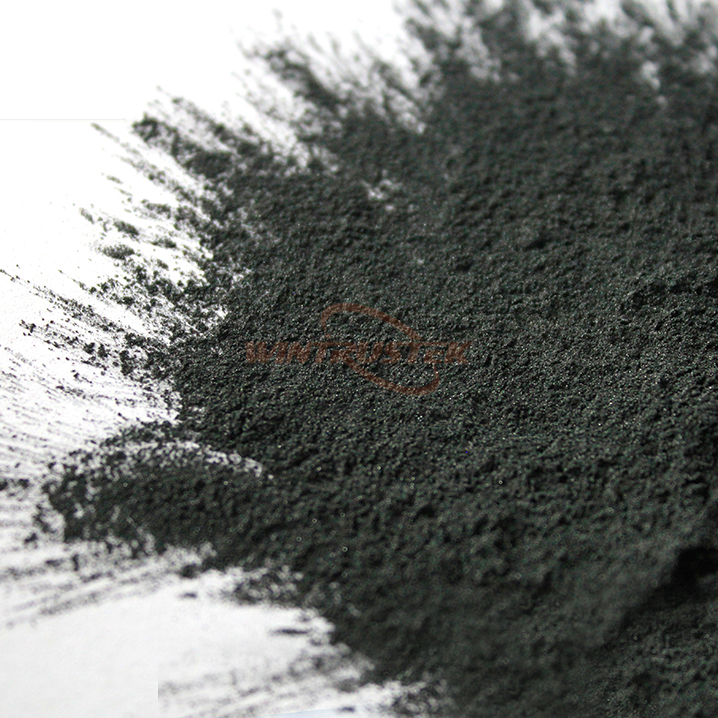

(Boron Carbide Powder Produced by Wintrustek)

Boron carbide powder is appreciated for its great hardness, low density, and outstanding thermal and chemical stability, as it can sustain temperatures exceeding 2700 K and is resistant to most acids and alkalis. Its tiny particle size allows for careful control of composite reinforcement and coating applications, improving wear resistance and mechanical performance. Boron carbide powder's versatility and proven performance ensure its long-term usefulness in cutting-edge industrial and research applications.

Advantages:

Boron carbide is one of the hardest materials on Earth, only surpassed by diamond and cubic boron nitride. This extreme hardness provides great wear resistance, making it perfect for high-speed cutting, grinding, and polishing.

Boron carbide is extremely durable. It is resistant to cracking and chipping, even under extreme situations, ensuring long-term performance and avoiding the need for frequent replacements.

Despite its hardness and endurance, boron carbide is extremely lightweight. Its low density makes it easier to handle and consumes less energy while in use, making it a more environmentally friendly option.

Boron carbide has excellent thermal stability, preserving its structure and performance even at high temperatures. This makes it a dependable alternative for applications demanding high temperatures.

Boron carbide provides outstanding performance while remaining cost-effective. Its extended life and efficiency can result in significant savings over time.

Applications:

1. National Defense and Personal Protection

This field is the most commonly recognized application for boron carbide. Hot-press sintering technology is used to convert the powder into dense ceramic plates for lightweight body armor inserts, ballistic panels for armed helicopter seats, and composite armor for tanks. Its "high hardness and low weight" qualities give superior protection while reducing the load on soldiers.

2. Nuclear Energy Industry

Because of its outstanding thermal neutron absorption capability, boron carbide is a primary material for nuclear reactor control rods, regulating rods, and safety shutdown rods. It also serves as a nuclear radiation shielding material to protect personnel and the environment.

3. Industrial Wear-Resistant Components

Blasting and Spray Nozzles: Boron carbide ceramic nozzles outlast traditional materials, making them essential components in effective sandblasting and waterjet cutting.

Mechanical Seal Rings: Used in pumps and valves under extreme working conditions, offering wear and corrosion resistance.

Grinding and Polishing Materials: Used as grinding paste or free abrasives for precision machining of ultra-hard materials like sapphire and cemented carbide.

4. Advanced Composite Materials: The Performance "Enhancer"

The addition of boron carbide powder as a reinforcing phase to metal matrices (such as aluminum), polymers, or other ceramic matrices considerably improves the composite materials' hardness, wear resistance, and neutron shielding ability. These are commonly utilized in aircraft, special-purpose vehicles, and other applications.

5. Other High-End and Precision Fields

Thermoelectric Materials: Certain boron carbide compositions have good thermoelectric performance at high temperatures, making them promising materials for waste heat power production.

Mirrors and Window Materials: Demonstrate excellent optical performance in specific wavelength bands.

Boron carbide is one of the strongest and most durable materials available in today's environment, where performance, efficiency, and lifespan are important. It is well-known for its remarkable thermal stability, chemical inertness, and cost-effectiveness, and it has proven to be a valuable asset in a variety of industries, including manufacturing and defense.