(Wintrustek Produces both Alumina and Mullite)

Alumina ceramic, sometimes referred to as aluminum oxide (Al2O3) or alumina, is an industrial oxide ceramic that is very thermally conductive and extremely durable. Because of theirs qualities, alumina ceramics are among the most popular ceramics for corrosive, wear, and structural settings. Usually made from bauxite, alumina ceramics can be molded by extrusion, injection molding, die pressing, isostatic pressing, slip casting, and diamond machining.

Mullite is produced by fusing silica and alumina in different combinations during the sintering process, creating a variety of materials. For dense solids, it is called mullite; for porous grades, it is called porous mullite or corundum.

There are two types of synthetic mullite (Al2O3–SiO2) products: porous and impervious forms. High strength and exceptional resistance to heat shock are combined in densely sintered (impervious) mullite. Porous mullite's low thermal expansion and comparatively high strength provide improved levels of thermal shock.

Mullite ceramics are employed in electrical insulation, furnaces, heaters, and wear and corrosion-resistant applications because of their high thermal shock and operating temperatures of up to 2910F (1600°C).

Key property for Alumina:

Temperature stability

High strength and hardness

Electrical insulation

Excellent resistance to wear and friction

The ability to withstand corrosion at elevated temperatures

Key property for Mullite:

Stability at high temperatures

Resistance to chemicals

Minimal expansion of heat

Strength of the mechanical

Insulation for electrical systems

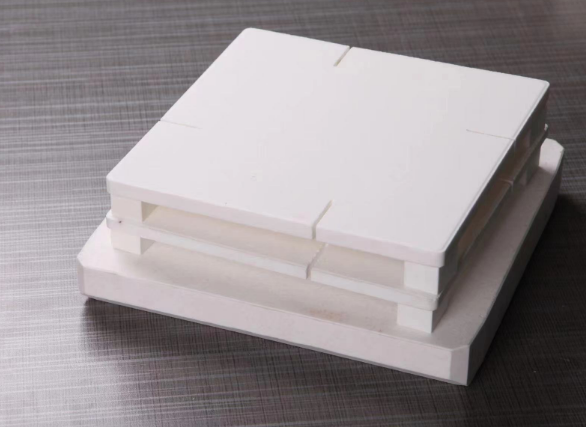

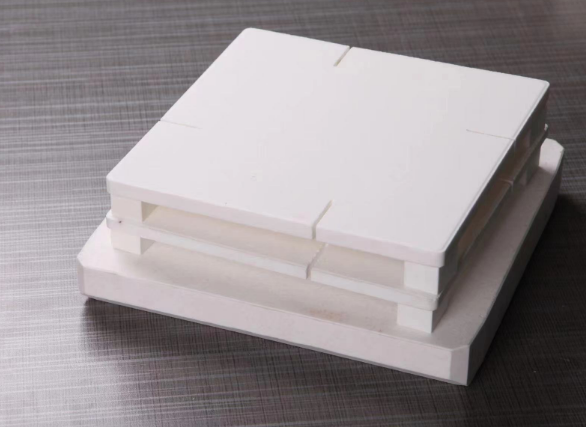

Structure and Composition

Aluminum oxide (Al2O3) with purity levels ranging from 75% to over 99% is the main ingredient used to make alumina ceramics. Hardness and wear resistance increase with alumina concentration. The crystalline structure provides outstanding durability and mechanical strength.

The material that makes up mullite ceramics is aluminum silicate (3AlO3·2SiO2). They are usually created by high-temperature burning of silica and alumina, which produces a lightweight structure with superior thermal stability. Mullite's resilience to thermal shock and minimal thermal expansion make it very valuable.

Physical Properties

Alumina's superior abrasion resistance makes it perfect for cutting tools and protective coatings.

Mullite's exceptional thermal characteristics and strength (6-7 Mohs hardness) make it a good choice for aircraft engineering and refractory linings.

Mechanical Properties

Alumina is well-known for its remarkable hardness, high compressive strength, and superior wear resistance. These characteristics make it a good choice for wear liners, grinding media, and high-load applications where abrasion is a major concern.

Mullite is less hard than alumina, yet it provides adequate mechanical strength while also being lower in weight. Its mechanical qualities are balanced by its capacity to resist large temperature fluctuations.

Thermal and Chemical Resistance

Alumina ceramics can resist extremely high operating temperatures while remaining structurally intact under severe wear. They are also highly resistant to acids and alkalis, making them perfect for chemically hostile situations.

Mullite ceramics stand notably for theirs high thermal shock resistance and low thermal conductivity. They work effectively in high-temperature furnaces, kiln linings, and refractory applications where thermal cycling occurs often.

Application:

Alumina's electrical insulating qualities make it suitable for electronic substrates and biomedical devices. Because of theirs exceptional wear resistance, alumina ceramics are commonly utilized in grinding balls, wear liners, and pipes where long service life is required.

Mullite's high temperature stability is critical for refractory linings and aircraft components.

To conclude, alumina ceramics are the chosen material for high-wear and chemically hostile situations due to theirs superior hardness, wear resistance, and chemical resilience. Mullite ceramics, on the other hand, have superior thermal stability and resilience to fast temperature swings, making them more suitable for high-temperature structural applications.