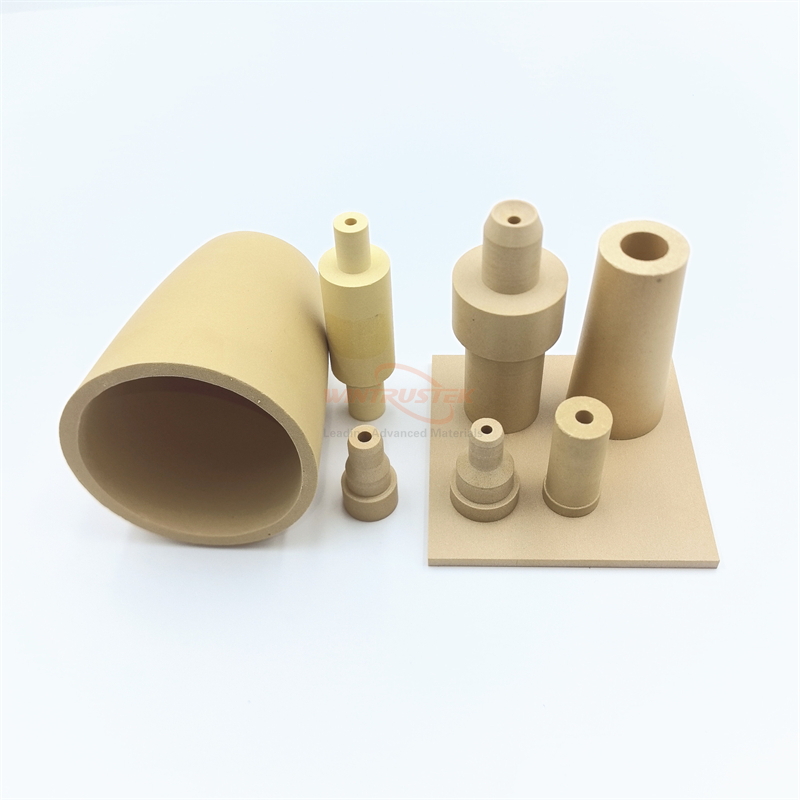

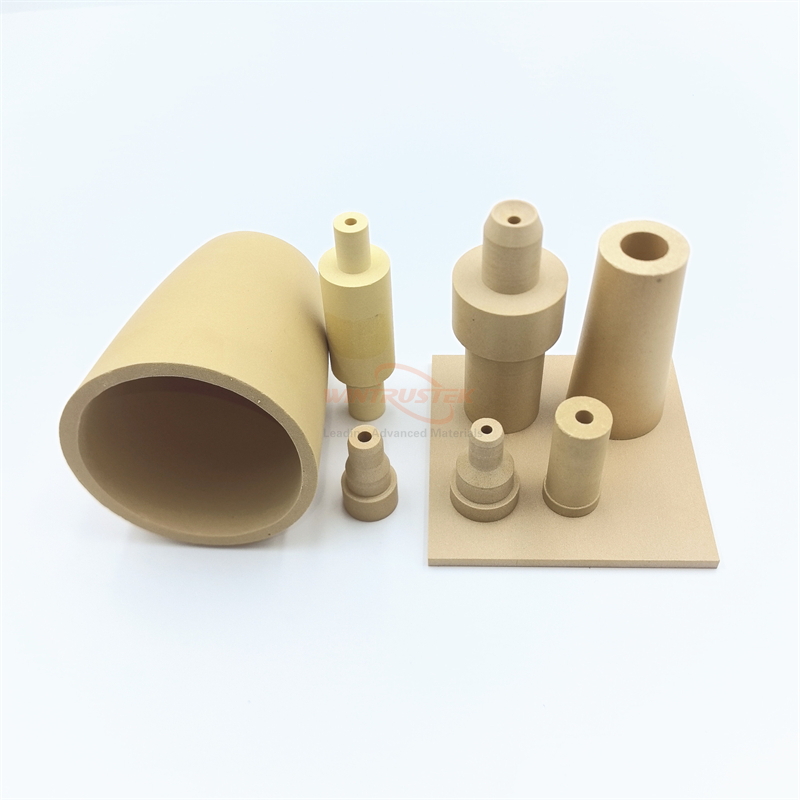

(MgO-ZrO2 Ceramic Nozzle Produced by Wintrustek)

Magnesium oxide stabilized zirconia (MgO-ZrO2) ceramics are gaining popularity in numerous industries due to their superior characteristics, especially at high temperatures. Zirconia ceramics, recognized for their high melting point and exceptional mechanical qualities, are commonly employed in demanding applications. However, stabilizing them with magnesium oxide improves their performance.

By enhancing the material's phase stability and preventing this phase shift, magnesium oxide stabilization of zirconia improves the material's overall performance. Zirconia's tetragonal phase is stabilized by MgO, which keeps it strong, durable, and resistant to wear at high temperatures. Applications requiring excellent thermal stability and structural integrity frequently use the MgO-ZrO2 ceramic.

This article focuses on MgO Stabilized Zirconia Nozzle.

MgO-ZrO2 nozzles are commonly employed in steel production for continuous casting ladles, converter tundishes, and converter taphole slag retention devices. They are mostly employed in the powder metallurgy business, which involves the smelting of ferrous and nonferrous metal powders such as nickel-based alloy powders, copper powders, stainless steel powders, iron powders, and other superalloy powders.

Advantages

Thermal shock resistance

Improved metallurgical quality

Long hours of life

Use high-quality raw materials

Highly resistant to the effects of oxygen

Consistent casting speed and controlled steel flow

Size and characteristics are flexible depending on casting conditions

Erosion resistance even in difficult casting circumstances

1. Metering Nozzles (inserts)

Our MgO-ZrO2 ceramic metering nozzles (inserts) provide high-performance solutions for harsh steelmaking environments such as continuous casting ladles, tundishes, and converter taphole slag retention mechanisms. Superior erosion and corrosion resistance are among the key properties, as is strong thermal shock stability. These features ensure that the nozzles can reliably last about 50 hours, reducing common problems like clogging, cracking, and expanding in size. The product line also includes continuous casting tundish upper nozzles, tundish quick-change nozzles, and fixed diameter nozzles.

2. Atomizing Nozzles

MgO-ZrO2 ceramic atomizing nozzles play an important role in the powder metallurgy industry, where they are used to smelt both ferrous and non-ferrous metal powders. These include a variety of materials such as nickel-based alloys, copper, stainless steel, iron, and superalloy powders. They are made to work better, being denser, highly resistant to damage from high temperatures and metal liquids, and able to handle sudden temperature changes consistently.

To meet specific application demands, different stabilizer materials and particle sizes are employed in their manufacture. We provide comprehensive customization, offering nozzles in various types and sizes tailored to individual operating conditions and requirements.