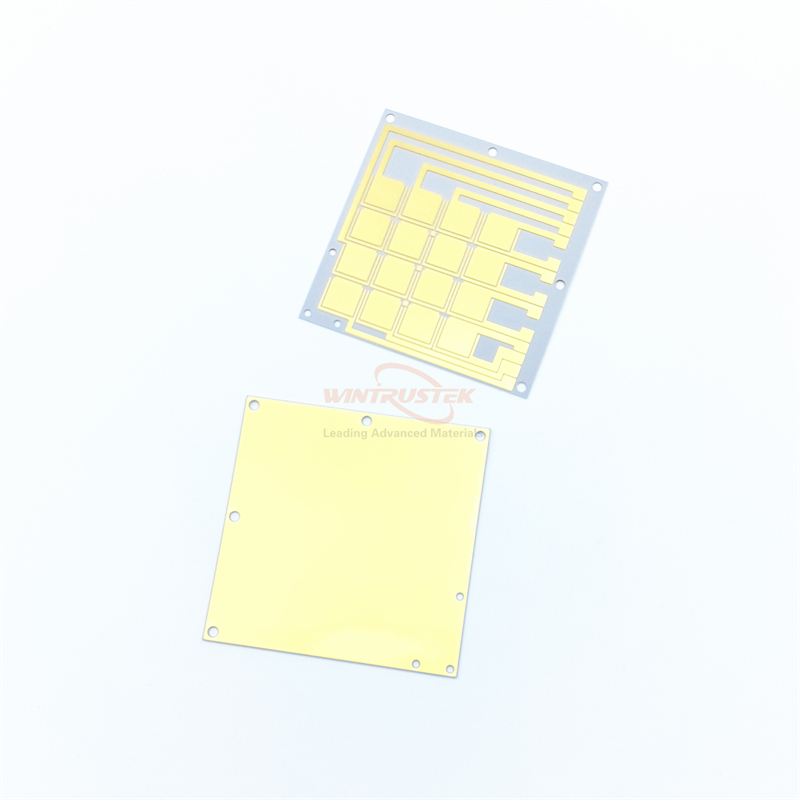

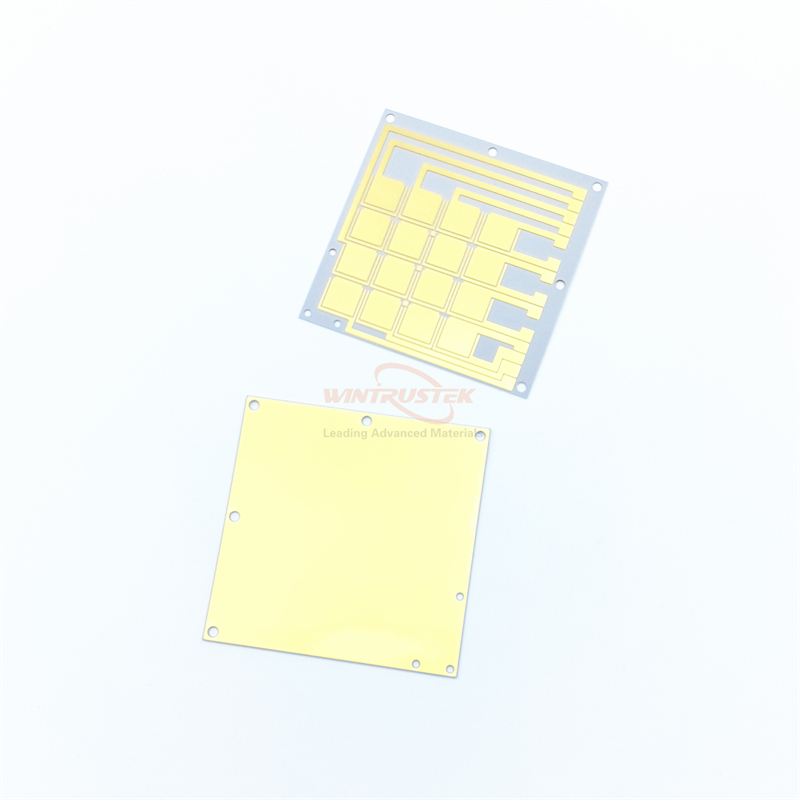

(AMB Ceramic Substrate Produced by Wintrustek)

The process of Active Metal Brazing (AMB) is an advancement of DBC technology. In order to link the ceramic substrate with the metal layer, a small quantity of active elements like Ti, Zr, and Cr in the filler metal react with the ceramic to generate a reaction layer that can be wetted by the liquid filler metal. AMB substrate has a stronger bond and is more reliable since it is based on the chemical interaction of ceramic and active metal at a high temperature.

AMB is the most recent advancement in ceramic substrates and provides the capability of producing heavy copper using either silicon nitride (Si3N4) or aluminum nitride (AlN). Since AMB uses a high temperature vacuum brazing process to braze pure copper onto ceramic, the standard metallization procedure is not utilized. Moreover, it provides a very dependable substrate with distinctive heat dissipation.

Active Metal Braze Ceramic PCB characteristics include:

1. Outstanding electrical properties

In high-frequency applications, ceramic substrates can reduce interference and signal loss due to their low dielectric constant and loss.

2. Greater heat conductivity

AMB ceramic PCBs are appropriate for high-power applications that demand effective heat dissipation because ceramic substrates have a substantially better thermal conductivity than conventional organic substrates.

3. Increased dependability

By creating a solid and long-lasting link between the metal layers and the ceramic substrate, the active metal brazing technique can greatly increase the PCB's dependability.

4. A stronger bond

The AMB ceramic PCB has a stronger bond than other ceramics since it is based on the reaction of ceramic and active components at a high temperature.

5. Economical

The ceramic substrate receives a metallization layer from the active metal layer, which can shorten PCB production times and lower costs.

Below are some common used ceramic materials for AMB:

1. AMB Alumina ceramic substrate

Al2O3 ceramics are the most affordable and commonly accessible. They have the most developed process and are the most affordable AMB ceramic substrates. Their exceptional qualities include high strength, high hardness, resistance to corrosion, resistance to wear, resilience to high temperatures, and superior insulating performance.

However, AMB alumina substrates are mostly utilized in applications with low power density and no stringent reliability requirements because of the low thermal conductivity and restricted heat dissipation capability of alumina ceramics.

2. AMB AlN ceramic substrate

Because of its high thermal conductivity (theoretical thermal conductivity 319 W/(m·K)), low dielectric constant, thermal expansion coefficient that is comparable to single crystal silicon, and good electrical insulation performance, AlN ceramic is a better material for circuit substrate packaging in the microelectronics industry than traditional Al2O3 and BeO substrate materials.

Currently, high-voltage and high-current power semiconductors such as high-speed rail, high-voltage converters, and DC power transmission are the primary applications for aluminum nitride ceramic substrates (AMB-AlN) made by the AMB process. However, the application range of AMB-AlN copper-clad substrates is limited because to their comparatively poor mechanical strength, which also affects their high and low temperature cycle impact life.

3. AMB Si3N4 ceramic substrate

The thick copper layer (up to 800μm), high heat capacity, strong heat transfer, and high thermal conductivity (>90W/(m·K)) are all features of AMB Si3N4 ceramic substrates. Specifically, it has a greater ability to transport current and better heat transfer when a thicker copper layer is welded to a relatively thin AMB Si3N4 ceramic.

For applications requiring high reliability, high heat dissipation, and partial discharge, such as wind turbines, photovoltaic inverters, new energy vehicles, and high-voltage DC transmission devices, AMB Si3N3 ceramic substrate is now the material of choice.