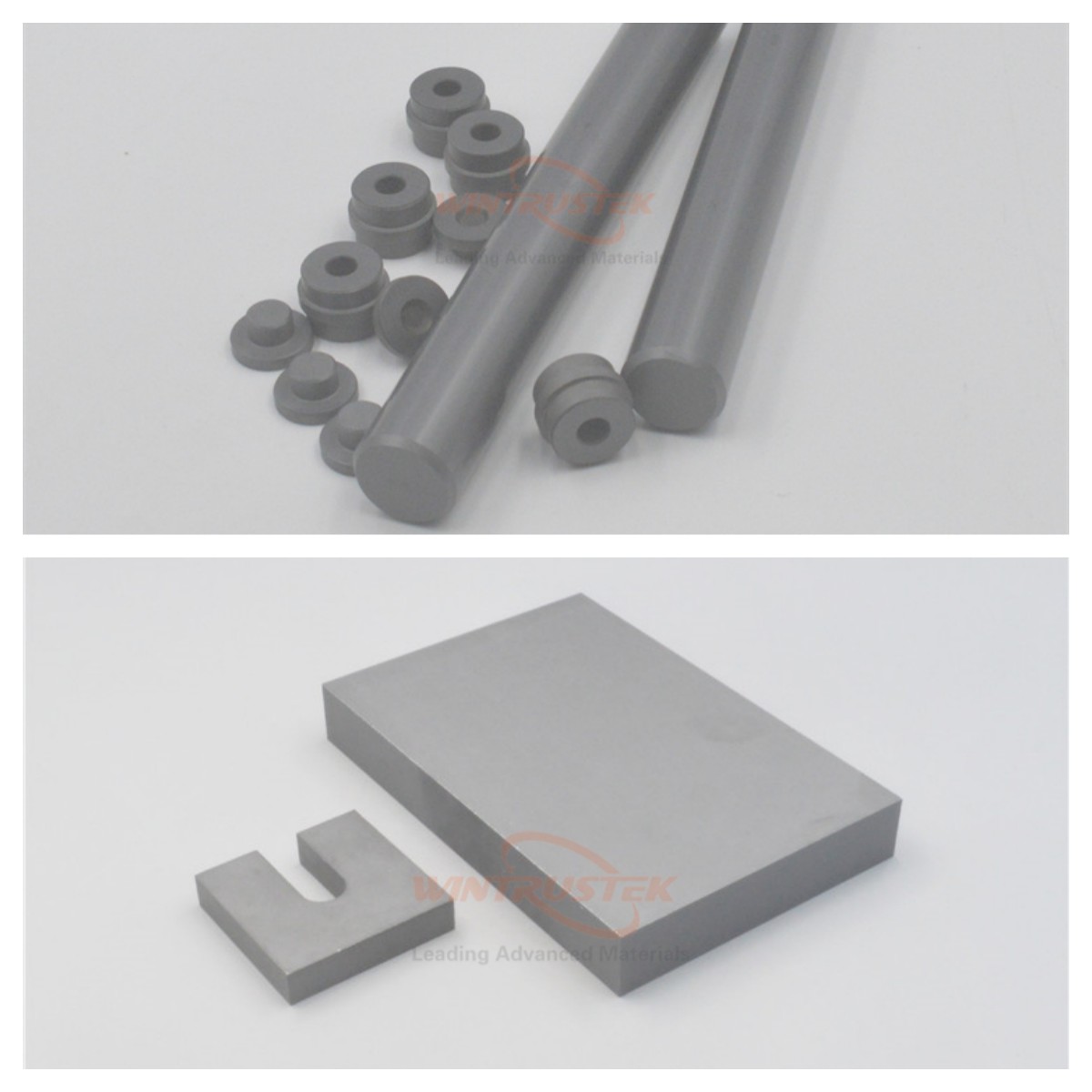

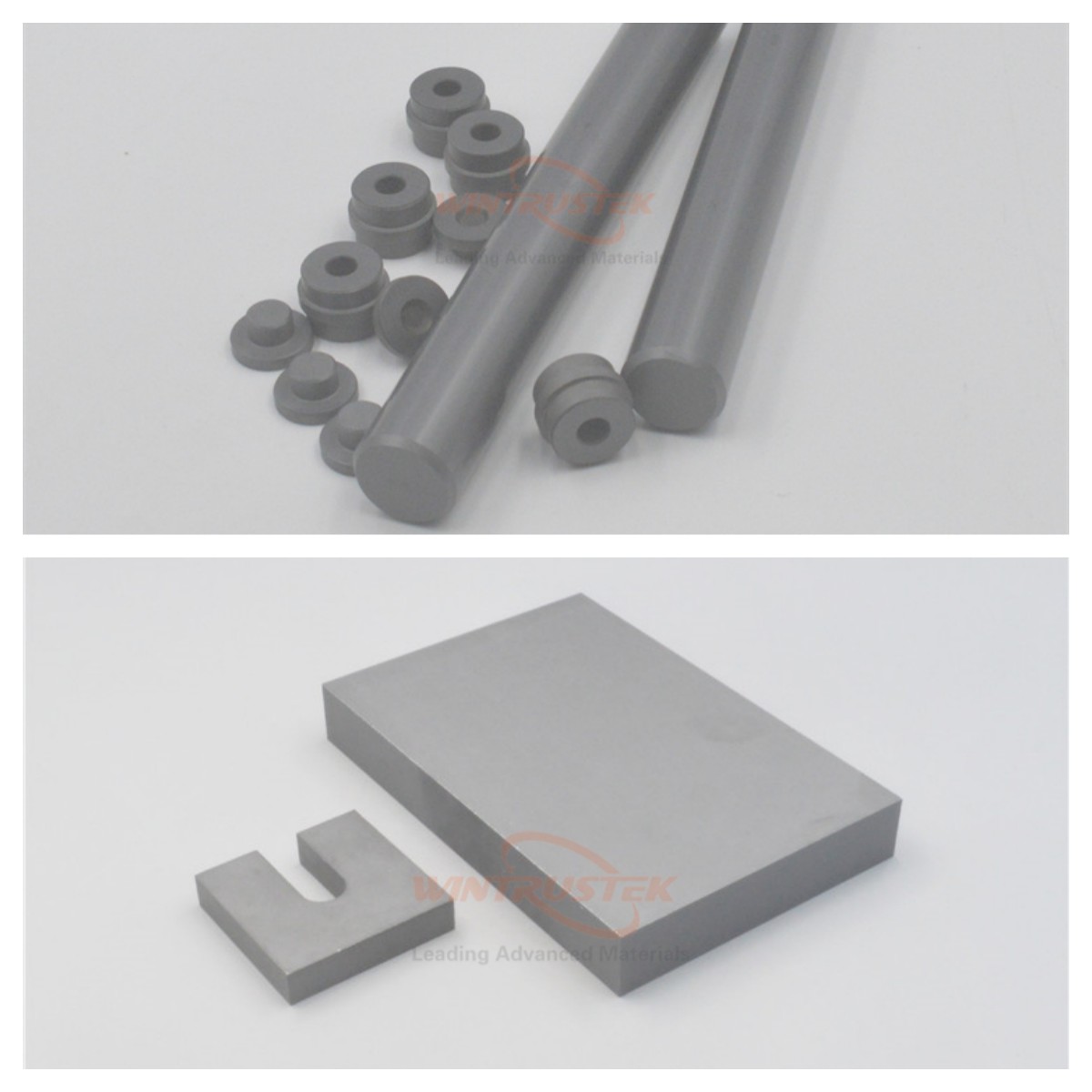

(SiC and B4C Produced by Wintrustek)

Engineers, designers, and procurement managers must make a key decision when selecting the appropriate advanced ceramic material. Boron carbide (B4C) and silicon carbide (SiC) are popular technical ceramics due to their high hardness, thermal stability, and resistance to severe conditions. However, they serve quite different purposes—and selecting the wrong one can have an impact on cost, durability, and overall system performance.

This detailed overview compares boron carbide with silicon carbide in terms of features, uses, benefits, and costs to help you decide which ceramic material is ideal for your unique project.

1. Overview of the Two Materials

Boron carbide (B4C)

Boron carbide is one of the hardest known materials, ranking only behind diamond and cubic boron nitride. It is highly lightweight, chemically inert, and commonly utilized in high-performance protective and wear-resistant applications.

Silicon carbide (SiC)

Silicon carbide is well-known for its high hardness, thermal conductivity, and superior thermal shock resistance. It is the workhorse of engineering ceramics and is often less expensive than boron carbide.

2. Property Comparison: B4C vs. SiC

Property

| Boron Carbide(B4C) | Silicon Carbide(SiC) |

| Density | Very low (~2.52 g/cm³) | Low/moderate (~3.1 g/cm³) |

| Hardness | Extremely high (≈ 30 GPa) | Very high (≈ 25–28 GPa) |

| Wear Resistance | Excellent | Very good |

| Fracture Toughness | Lower (more brittle) | Higher (better shock resistance) |

| Thermal Conductivity | Moderate | Very high (excellent heat dissipation) |

| Chemical Resistance | Outstanding | Excellent |

| Ballistic Performance | Superior | Good but heavier |

| Cost | Higher | More cost-effective |

3. When to Choose Boron Carbide

3.1 For Weight-Critical Applications

Boron carbide is one of the lightest technical ceramics, making it perfect for weight reduction without compromising hardness.

3.2 For High-Level Ballistic Protection

B4C is the best choice for:

Its unparalleled toughness enables it to block high-velocity bullets with minimum weight.

3.3 For Extreme Abrasion Environments

Boron carbide excels at:

Its wear resistance frequently results in a longer lifespan than SiC in the worst situations.

4. When to Choose Silicon Carbide

4.1 For High Thermal Conductivity Applications

Silicon carbide is suitable for:

It quickly dissipates heat and can withstand extreme temperature swings without cracking.

4.2 For Cost-Sensitive Industrial Projects

SiC is popular because it provides good performance at a lower cost:

Nozzles

Bearings

Mechanical seals

Kiln furniture

Automotive components

4.3 For Situations Requiring Higher Toughness

SiC is less brittle than B₄C, making it more durable against impacts, vibrations, and thermal cycling.

5. Cost Comparison

While actual pricing depends on purity, size, and the manufacturing process:

Boron carbide is much more expensive due to raw material costs and sophisticated sintering.

Silicon carbide is more cost-effective, particularly for big components or high-volume manufacture.

B₄C is the top choice for achieving maximum performance at any cost.

If the performance-to-price ratio is important, SiC is usually the top choice.

6. Industries That Benefit from Each Material

Boron Carbide

Silicon Carbide

7. Which Material Should You Choose?

Select Boron Carbide if your application demands

Optimal hardness

Lightest feasible weight

Excellent abrasion resistance

Superior ballistic performance

Corrosion resistance in severe settings

Select Silicon Carbide if your application demands

Lower material costs

High thermal conductivity

Improved fracture toughness

Resistance to thermal shock

Large or complexly formed portions

8. Conclusion

Both boron carbide and silicon carbide are high-performance advanced ceramics, yet they excel in distinct areas.

Boron carbide is unparalleled in hardness, weight reduction, and ballistic performance, making it excellent for armor and high-wear settings.

Silicon carbide has excellent thermal stability, toughness, and cost-effectiveness, making it an ideal material for industrial and high-temperature applications.

The best ceramic for your application is determined by its specific requirements. For many applications, balancing weight, hardness, thermal behavior, toughness, and budget is critical to selecting the best material.