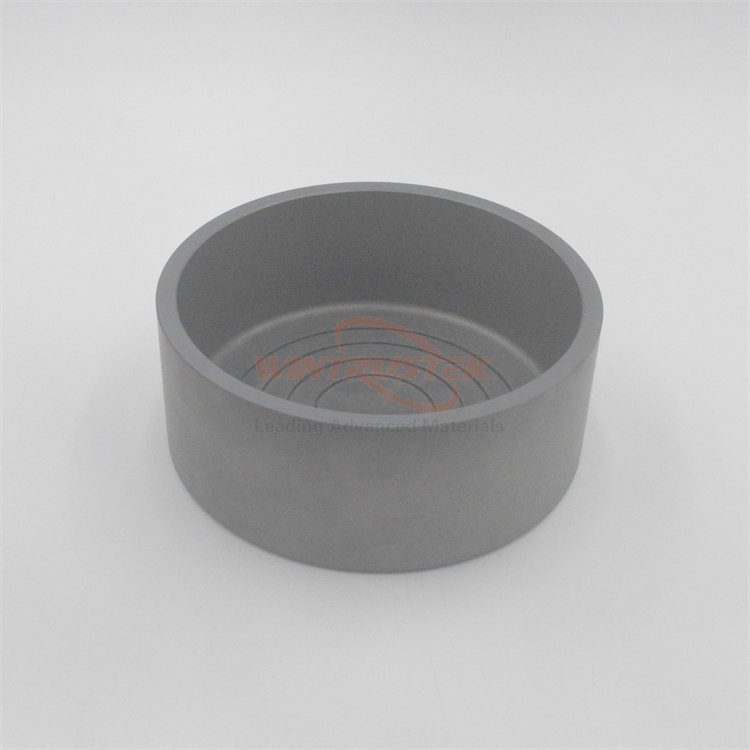

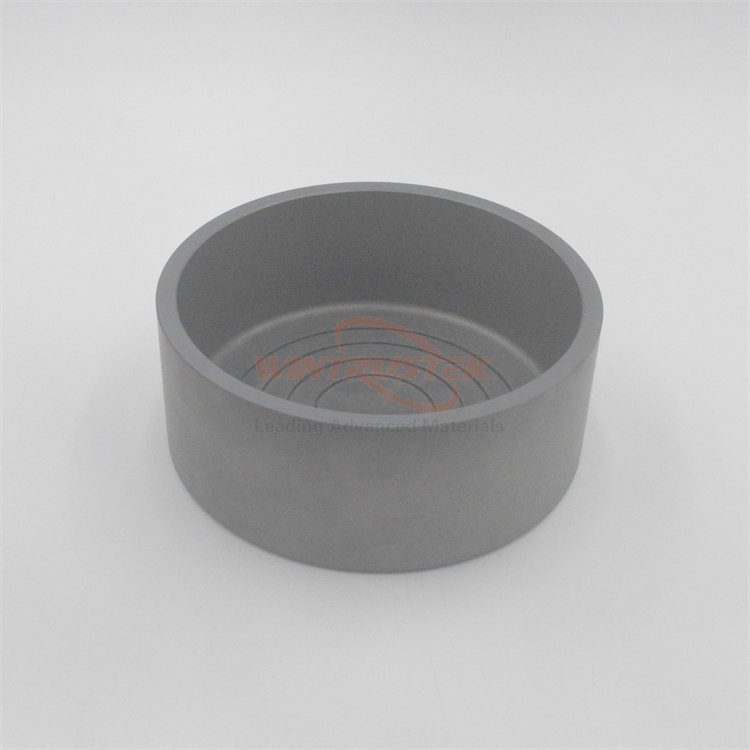

(Reaction Bonded Silicon Carbide Produced by Wintrustek)

Among the strongest ceramics, silicon carbide maintains its strength and hardness at high temperatures, making it one of the materials with the best resistance to wear. SiC also provides exceptional thermal shock resistance, a low thermal expansion index, and strong thermal conductivity. In addition, it weighs half as much as steel.

Reaction bonding, also known as reaction sintering, is a crucial process for creating dense covalent ceramics. Melted silicon is infused into a porous carbon or graphite preform to create reaction-bonded silicon carbide. Its production method with a coarse grain is the least expensive. It offers greater thermal conductivity but somewhat lower hardness and usage temperature.

Process:

1. Heat silicon, plasticizers, and coarse silicon carbide together.

2. Shape the mixture into the desired form.

3. After burning these materials, prepare them for additional machining.

Properties:

High strength

Excellent chemical resistance

Excellent Wear Resistance

Good Thermal Shock Resistance

RBSiC is frequently utilized in larger wear components for mining and other sectors, as well as in pumps, mechanical seals, bearings, pipe liners, flow control chokes, and other applications requiring high wear resistance and dimensional stability.

Apart from reaction bonded silicon carbide, Wintrustek also can produce pressureless sintered silicon carbide (SSiC) and recrystallized silicon carbide (RSiC).

Silicon carbide ceramics are used in several sectors and are made using various techniques. Sintering happens at greater temperatures, reaction bonding happens at lower temperatures, and recrystallization yields more pure silicon carbide products. Wintrustek offers high-quality silicon carbide ceramics from various production techniques. For any questions or requirements, you are welcome to send the inquiry to our sales.