As integrated circuits have become a strategic national industry, many semiconductor materials have been researched and developed, and Aluminum Nitride is undoubtedly one of the most promising semiconductor materials.

Aluminum Nitride Performance Characteristics

Aluminum Nitride (AlN) has the characteristics of high strength, high volume resistivity, high insulation voltage, coefficient of thermal expansion, good matching with silicon, etc. It is not only used as a sintering aid or reinforcing phase for structural ceramics but also used in the field of ceramic electronic substrates and packaging materials, which has been booming in recent years, and its performance far exceeds that of Alumina. Aluminum Nitride ceramics have excellent overall performance, are ideal for semiconductor substrates and structural packaging materials, and have significant application potential in the electronics industry.

Application of Aluminum Nitride

1. Piezoelectric device applications

Aluminum Nitride has high resistivity, high thermal conductivity, and a low coefficient of expansion similar to silicon, which is the ideal material for high-temperature and high-power electronic devices.

2. Electronic packaging substrate materials

Beryllium Oxide, Alumina, Silicon Nitride, and Aluminum Nitride are some of the most common materials used for ceramic substrates.

Among the existing ceramic materials that can be used as substrate materials, Silicon Nitride ceramics have the highest flexural strength, good wear resistance, and the best comprehensive mechanical properties of ceramic materials, while their coefficient of thermal expansion is the smallest. Aluminum Nitride ceramics have high thermal conductivity, good thermal shock resistance, and still have good mechanical properties at high temperatures. It can be said that, from the point of view of performance, Aluminum Nitride and Silicon Nitride are currently the most suitable for use as electronic packaging substrate materials, but they also have a common problem: their price is high.

3. Application to light-emitting materials

In terms of photoelectric conversion efficiency, aluminum nitride (AlN) has a direct bandgap semiconductor band maximum width of 6.2 eV, which is higher than the indirect bandgap semiconductor. AlN, as an important blue and ultraviolet light-emitting material, is used in ultraviolet and deep ultraviolet light-emitting diodes, ultraviolet laser diodes, ultraviolet detectors, etc. AlN and III-group nitrides like GaN and InN can also form a continuous solid solution, and the band gap of its ternary or quaternary alloy can be adjusted continuously from the visible band to the deep ultraviolet band, making it an important high-performance light-emitting material.

4. Application to substrate materials

AlN crystal is the ideal substrate for GaN, AlGaN, and AlN epitaxial materials. Compared with sapphire or SiC substrates, AlN and GaN have better thermal matching and chemical compatibility, and the stress between the substrate and epitaxial layer is smaller. Therefore, AlN crystals as GaN epitaxial substrates can significantly reduce the defect density in the device and improve its performance, which has a very good prospect of application in the preparation of high-temperature, high-frequency, and high-power electronic devices. In addition, using AlN crystals as an AlGaN epitaxial material substrate with high aluminum (Al) components can also effectively reduce the defect density in the nitride epitaxial layer and greatly improve the performance and lifetime of nitride semiconductor devices. Based on AlGaN, a high-quality day blind detector has been successfully applied.

5. Application to ceramics and refractory materials

Aluminum Nitride can be used in structural ceramic sintering; prepared Aluminum Nitride ceramics have not only better mechanical properties and flexural strength than Al2O3 and BeO ceramics, but also higher hardness and corrosion resistance.Using the heat and erosion resistance of AlN ceramics, they can be used to make crucibles, Al evaporation dishes, and other high-temperature corrosion-resistant parts. In addition, pure AlN ceramics for colorless transparent crystals, with excellent optical properties, can be used as transparent ceramics for electronic optical devices and equipment for high-temperature infrared windows and rectifier heat-resistant coating.

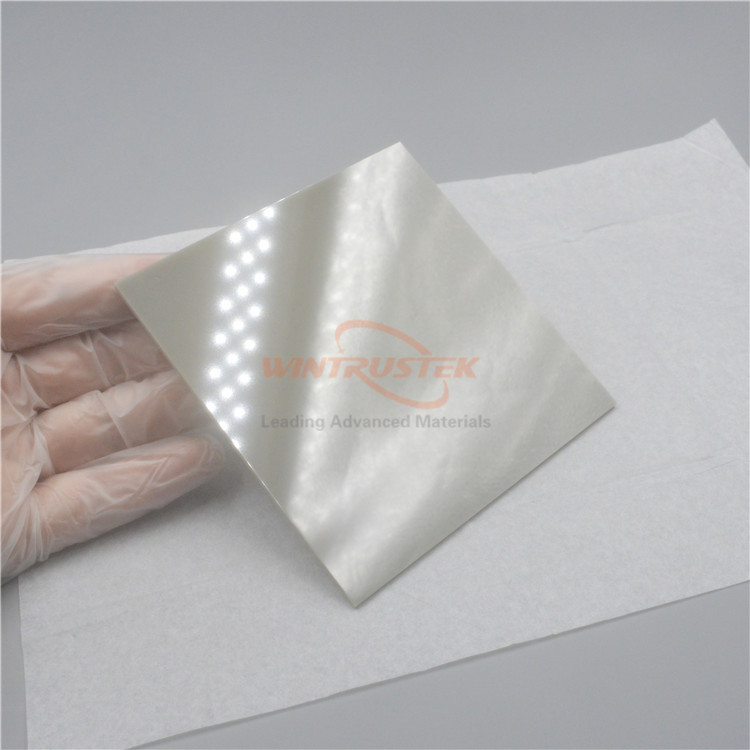

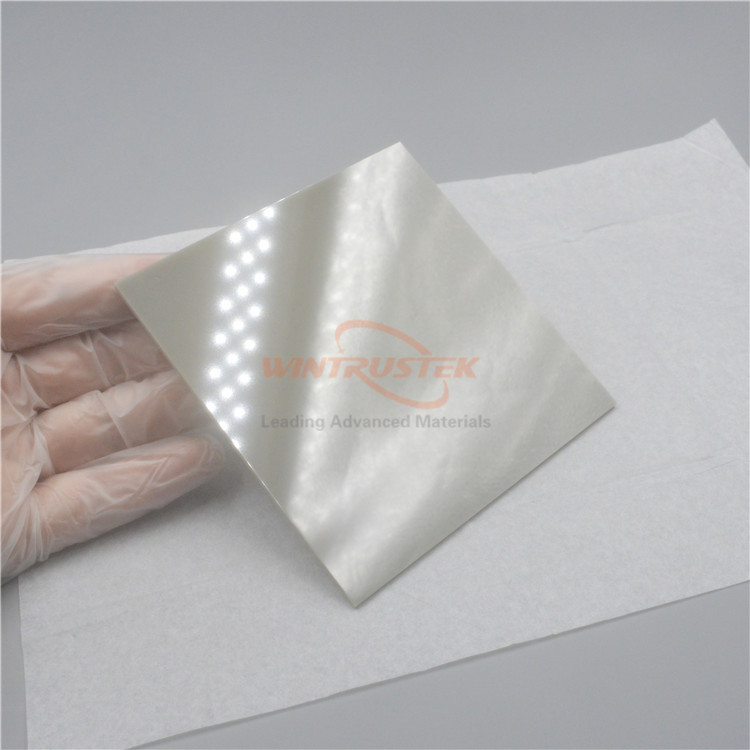

Double Sides Polished Aluminum Nitride AlN Ceramic Substrates From WINTRUSTEK