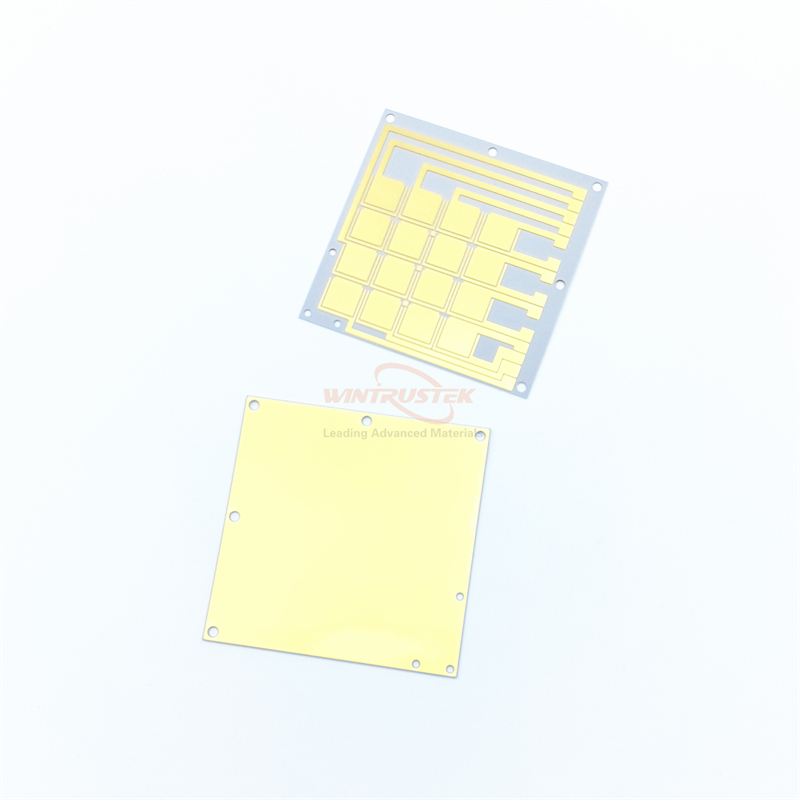

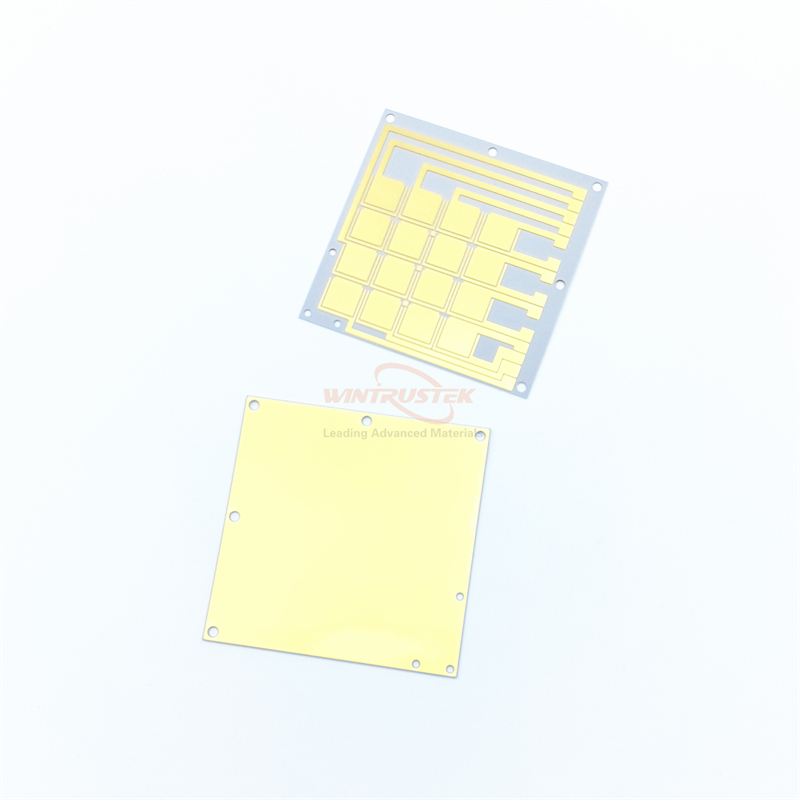

(Isigaxa se-ceramic substrateKukhiqizwa nguI-WintrustEK)

Inqubo yensimbi esebenzayo yensimbi (ama-atm) ukuthuthuka kweI-DBCubuchwepheshe. Ukuze uxhumaniseI-Ceramic substrateNgesendlalelo sensimbi, inani elincane lezinto ezisebenzayo ezifana ne-TI, ZR, kanye ne-cr ku-filler insimbi usabela nge-ceramic ukukhiqiza isendlalelo sokuphendula esingafakwa nge-filler filler metal. I-Ambstrate substrate ine-bond enamandla futhi ithembeke ngokwengeziwe kusukela kususelwa ekuxhumaneni kwamakhemikhali kwensimbi ye-ceramic nesebenzayo ekushiseni okuphezulu.

I-AMB iyinhlangano yakamuva kakhulu ngaphakathiAma-substrate we-Ceramicfuthi ihlinzeka amandla okukhiqiza ithusi elisindayo lisebenzisa nomasilicon nitride (si3n4) or I-Aluminium nitride (ALN). Njengoba i-amber isebenzisa inqubo ephezulu yokushisa i-vacuum brazing inqubo yokuvuselela ithusi elimsulwa ku-ceramic, inqubo ejwayelekile yensimbi ayisetshenziswa. Ngaphezu kwalokho, ihlinzeka nge-substrate ethembeke kakhulu ngokudicilela phansi okuhlukile kokushisa.

Izici ze-PCB ze-PCB zensimbi ezisebenzayo ze-PCB zifaka:

1. Ugesi oveleleizakhiwo

Ezisetshenzisweni zemvamisa ephezulu, ama-surfatic we-ceramic anganciphisa ukuphazamiseka nokulahleka kwesiginali ngenxa yokudla kwawo okuphansi okuqhubekayo nokulahleka.

2. Ukuvuselelwa Okukhulu Ukushisa

Ama-PCbs we-AMB Curamic alungele izinhlelo zokusebenza ezinamandla afunwa ukudicilela phansi okusebenzayo ngoba ama-substrates we-ceramic anokuvuka okungcono kakhulu okushisayo kunezinto ezijwayelekile ze-organic.

3. Ukwanda kuncishisiwe

Ngokwakha ukuxhumana okuqinile nokuhlala isikhathi eside phakathi kwezendlalelo zensimbi kanye ne-ceramic substrate, inqubo esebenzayo yensimbi yensimbi ingakhuphula kakhulu ukuncika kwe-PCB.

4. Isibopho esinamandla

I-AMBER CURAMIC PCB inesibopho esinamandla kunamanye ama-ceramics kusukela isuselwa ekuphendukeni kwezakhi ze-ceramic nezama-asebenzayo ekushiseni okuphezulu.

5. Ezomnotho

I-ceramic substrate ithola ungqimba lwensimbi kusuka ku-waler yensimbi esebenzayo, engafushanisa izikhathi zokukhiqiza ze-PCB nezindleko eziphansi.

Ngezansi ezinye izinto ezijwayelekile ze-ceramic ze-amba:

1. Ithumba Khu uzaloumna cI-Eramic Substrate

I-AL2O3 Curamics yiyona ebiza kakhulu futhi evame ukutholakala. Banenqubo ethuthuke kakhulu futhi bayiziqubu ezingabizi kakhulu ze-ceramic substrates. Izimfanelo zabo ezihlukile zibandakanya amandla aphezulu, ubunzima obuphezulu, ukumelana nokugqwala, ukumelana nokugqoka, ukubekezelela amazinga okushisa aphezulu, nokusebenza okuphezulu okuletha amandla.

Kodwa-ke, ama-Alumina substrates asetshenziswa kakhulu kwizicelo ezinamandla amakhulu anamandla futhi azikho izidingo ezinqunyelwe zokwethenjwa ngenxa yokuvuselelwa okuphansi okushisayo kanye namandla okuhlaselwa ukushisa okuvinjelwe ama-alumina ceramics.

2. I-AMS ALN Ceramic Substrate

Ngenxa yokuvuselelwa kwayo okuphezulu okuphezulu (i-theoretical thermal countrivity 319 w / (m · k)), i-dielectric ephansi eguquguqukayo eqhathaniswa ne-silicon eyodwa ye-crystal, kanye nokusebenza okuhle kogesi, izinto ezingcono zokwenza izinto zendabuko kunezinto zendabuko ze-AL2O3 nezinto zokwakha ezingezansi.

Njengamanje, ama-semiconductures aphezulu aphezulu kanye nama-semiconductors aphezulu wamanje afana nesitimela esisheshayo, abaguquli bamandla aphezulu, futhi ukuhanjiswa kwamandla we-DC kuyizicelo eziyinhloko ze-aluminium nitride substrates (ama-aln-aln) enziwe yinqubo ye-aluminium nitride ceramic (ama-aln Kodwa-ke, uhla lwesicelo lwe-AMB-ALN Copper-Clad Substrates lulinganiselwe ngoba ngokuqhathaniswa nokuqhathaniswa nokuqhathaniswa kwemishini okungokomshini, okubuye kuthinte impilo yabo ephezulu futhi ephansi yokushisa umjikelezo wokuphila.

3. I-AM SI3N4 Ceremic Substerstrate

Ungqimba lwe-Copper oluwugqinsi (kuze kube ngu-800μm), umthamo wokushisa ophakeme, ukudluliswa okuqinile kokushisa, kanye nokuvuselelwa okuphezulu okushisayo (> 90W / (m · k) Ngokukhethekile, inamandla amakhulu okuhambisa ukudluliswa kokushisa kwamanje nokungcono lapho ungqimba lwamakhulu ethukudla lufakwe ku-anm elincanyana ye-si3n4 ceramic.

90W / (m · k) Ngokukhethekile, inamandla amakhulu okuhambisa ukudluliswa kokushisa kwamanje nokungcono lapho ungqimba lwamakhulu ethukudla lufakwe ku-anm elincanyana ye-si3n4 ceramic.