(I-WintrustEKKukhiqiza bobabiliUmsindonana-Inxusa)

U-Alumina Ceramic, kwesinye isikhathi kubizwa ngokuthiI-Aluminium Oxide (Al2o3) or umsindona, iyi-ceramic ye-oximic yezimboni esebenza kahle kakhulu futhi ehlala isikhathi eside kakhulu. Ngenxa yezimpawu zabo,I-Alumina ceramicsziphakathi kwama-ceramics athandwa kakhulu ezilungiselelweni ezilonakalisayo, zokugqoka, kanye nezakhiwo. Imvamisa eyenziwe nge-bauxite, ama-alumina ceramics angabunjwa ngokukhishwa, ukuphathwa kokujoyina, kufa ngokucindezela, ukucindezela okuzayo, ukushelela maini.

Inxusakukhiqizwa yi-silica ethambekele kwe-alumina kanye ne-alumina ekuhlanganisweni okuhlukile ngesikhathi senqubo yesono, kwakha izinto ezahlukahlukene. Ngama-solids aminyene, ibizwa ngokuthi yi-MUllite; Kumabanga aphoqayo, ibizwa ngokuthi yi-porous mullite noma i-corundum.

Kunezinhlobo ezimbili zokwenziwa kwe-Mullite (Al2o3-Sio2) Imikhiqizo: Amafomu angenamqondo nezingangeneki. Amandla aphezulu kanye nokumelana okuhlukile kokushaqeka kokushisa ahlanganiswe endaweni enesono kakhulu (engenasisekelo). Ukunwetshwa okuphansi kukaPorous Mellite kanye nokuqhathanisa amandla aphezulu kuhlinzeka ngamazinga athuthukisiwe okuthuthumela okushisayo.

Mbullite ceramicsbaqashwa ekufakweni kukagesi, izimfanelo, ama-heater, kanye nokugqokwa kanye nezicelo ezivimbela ukugqwala ngenxa yokushaqeka okuphezulu okushisayo kanye namazinga okushisa okusebenza afinyelela ku-2910f (1600 ° C).

Impahla ebalulekile yeUmsindona:

Ukuqina kokushisa

Amandla aphezulu nobulukhuni

Ukufakwa kukagesi

Ukumelana okuhle kakhulu ukugqoka nokuxabana

Amandla okumelana nokugqwala emazingeni okushisa aphakeme

Impahla ebalulekile yeInxusa:

Ukuqina emazingeni okushisa aphezulu

Ukumelana namakhemikhali

Ukunwetshwa okuncane kokushisa

Amandla omshini

Ukufakwa kwezinhlelo zikagesi

Ukwakheka nokwakheka

I-Aluminium Oxide (Al2o3)Ngamazinga okuhlanza kusuka kuma-75% kuya kwangama-99% isithako esiyinhloko esisetshenziselwa ukwenza ama-alumina ceramics. Ubulukhuni kanye nokugqoka ukumelana nokuqina kwe-alumina. Isakhiwo se-Crystalline sinikeza ukuqina okuvelele kanye namandla emishini.

Impahla eyenziwayombullite ceramicsIngabe i-aluminium bulicate (3alo3·2SiO2). Zivame ukudalwa ngokushiswa okushisa okuphezulu kwe-silica ne-alumina, ekhiqiza isakhiwo esingasindi ngokuqina okuphezulu okushisayo. Ukuqina kukaMullite ku-Thermal Shock kanye nokunwetshwa okuncane okushisayo kwenza kube yigugu kakhulu.

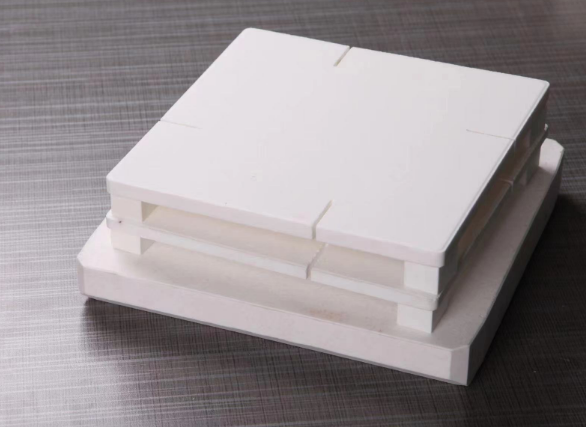

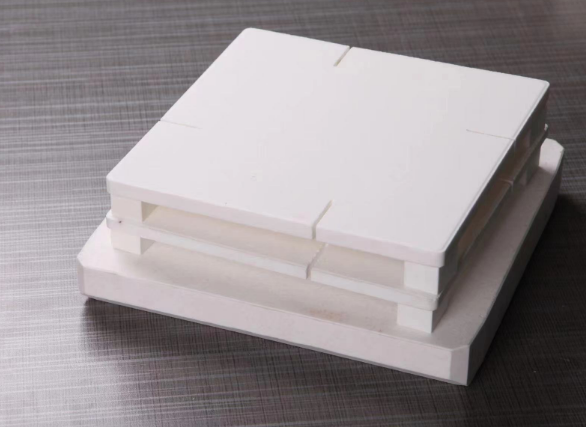

Izakhiwo Ezibonakalayo

UmsindonaUkumelana nokuqina okuphezulu kwe-abrasion kwenza kube fanele ukunciphisa amathuluzi nezingubo zokuvikela.

InxusaIzici ezihlukile ezi-Thermal kanye namandla (6-7 Mohs Hardness) zikwenza kube yisinqumo esihle sonjiniyela bezindiza kanye nokufafazwayo.

Izakhiwo zemishini

Umsindonayaziwa kakhulu ngobulukhuni bayo obumangalisayo, amandla aphezulu acindezelwe, nokuphikiswa okuphakeme kokuqina. Lezi zici zikwenza kube yisinqumo esihle sokugqoka ama-liners, imidiya yokugaya, nezicelo eziphezulu zokulayisha lapho i-abrasion iyinkinga enkulu.

Inxusaayilukhuni kune-alumina, nokho inikezela amandla anele emishini ngenkathi futhi ephansi ngesisindo. Izimfanelo zayo zemishini zilinganiselwa amandla alo okumelana nokushintshashintsha kwezinga lokushisa elikhulu.

Ukumelana okushisayo nokwekhemikhali

I-Alumina ceramicskungamelana namazinga okushisa aphezulu kakhulu ngenkathi kusele ngokuhlelekile ngaphansi kokugqoka okunzima. Baphinde bamelana kakhulu nama-acid kanye ne-alkalis, bebenza balungele izimo ezinobutha ngamakhemikhali.

InxusaAma-ceramics akhona ngokuphawuleka kwawo ukumelana nokuvuselelwa okuphezulu okushisayo nokuvuselelwa okuphansi okushisayo. Basebenza ngempumelelo ezindlini zokushisa okuphezulu, ama-kiln linings, nezinhlelo zokusebenza zokuya kabusha lapho kwenzeka khona ukuhamba nge-cycling okushisayo kaningi.

Isicelo:

UmsindonaIzimfanelo zikagesi ezifakayo zizenza zilungele ama-substrates kagesi namadivayisi we-biomedical. Ngenxa yazo ukumelana nokugqoka okuhlukile, ama-alumina ceramics ajwayele ukusetshenziselwa ukugaya amabhola, agqoke amapayipi, namapayipi lapho kutholakala khona inkonzo yenkonzo ende.

InxusaUkuqina kokushisa okuphezulu kubaluleke kakhulu kuma-linings okuzenzakalelayo nezinto zezindiza.

Ukuphetha,I-Alumina ceramicsIngabe impahla ekhethiwe yezimo eziphakeme nezinobutha eziphakemeyo ngenxa yobulukhuni obukhulu, ukugqoka ukugqokwa, nokuqina kwamakhemikhali.Mbullite ceramics, ngakolunye uhlangothi, sinokuqina okuphezulu okushisayo nokuqina kokushisa okusheshayo kokushisa, kubenza balungele izinhlelo zokusebenza eziphezulu zokushisa.