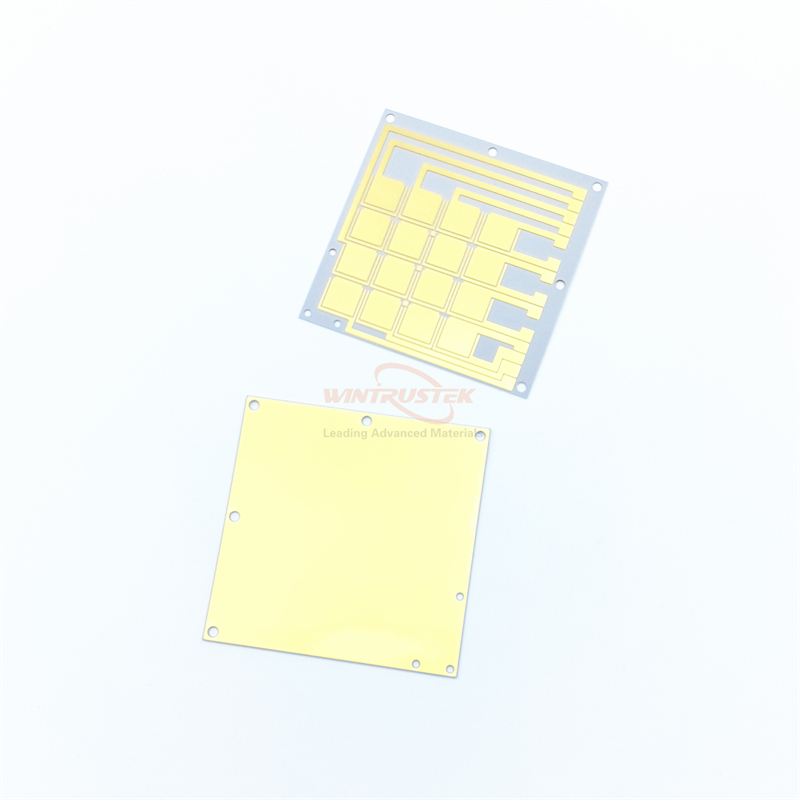

(Kiag ceramic substrateTsim los ntawmWintrustek)

Cov txheej txheem ntawm cov khoom siv hlau ntaus hlau (amb) yog kev nce qib ntawmDbcthev naus laus zis. Txhawm rau txuas covCeramic substrateNrog cov txheej hlau, qhov ntau me me ntawm cov ntsiab lus zoo li ti, zr, thiab CR hauv txheej txheem cov tshuaj tiv thaiv uas tuaj yeem tsim los ntawm cov kua muab cov hlau. Am Substrate muaj qhov ua kom muaj zog dua thiab yog nyob ntawm kev sib cuam tshuam ntawm Ceramic thiab cov hlau ua haujlwm ntawm qhov kub.

Amb yog qhov kev txhim kho tshiab tshaj plaws hauvCeramic substratesthiab muab cov peev xwm ntawm kev ua luam tawm hnyav tooj liab siv ib qhoSilicon Nitride (Si3N4) or Aluminium Nitride (Aln)Cov. Txij thaum HWJCHIM siv lub tshuab hluav taws xob kub siab rau Breaze Ntshuam Ntshuam Dawb Rau Ceramic, cov qauv kev ntsuas me me tsis siv. Ntxiv mus, nws muab ib qho kev ntseeg siab heev nrog kev sib cav sib ceg tsis sib xws.

Cov hlau nquag muag cov cim pcb muaj xws li:

1. Koj Cov Hluav Taws XobCov Khoom Siv

Hauv kev siv cov ntawv thov siab, cov ceramic submenates no tuaj yeem txo thiab teeb liab poob vim lawv qhov qis dielectric tas li thiab poob.

2. Kev Tshaj Tawm Ntau Lawm

Cov ceramic PCBS tsim nyog rau cov kev siv hluav taws xob siab uas xav tau cua sov ua kom zoo dua li cov khoom siv hluav taws xob zoo dua li cov organic substrates.

3. Kev vam khom ntxiv

Los ntawm kev tsim cov khoom siv ruaj khov thiab ntev ntev ntawm cov hlau hlau thiab cov txheej txheem sib xyaw ua ke, cov txheej txheem hlau nplaum tau zoo heev ntxiv rau PCB lub siab tau.

4. Lub zog ua kom muaj zog

Lub ceramic pcb muaj qhov kev sib tw ua kom muaj zog dua li lwm qhov kev sib raug zoo vim tias nws yog cov tshuaj tiv thaiv kab mob ceramic thiab cov khoom siv ua haujlwm ntawm qhov kub thiab txias.

5. Kev Lag Luam

Cov txheej txheem ceramic tau txais cov txheej txheem me me ntawm cov txheej hlau hlau, uas tuaj yeem ua rau PCB cov sijhawm thiab tus nqi qis dua.

Hauv qab no yog qee cov ntaub ntawv siv cov ntaub ntawv sib xyaws rau lub amb:

1. Loj AlUMINA Ceramic substrate

Al2O3 Ceramics yog qhov pheej yig tshaj plaws thiab feem ntau siv tau. Lawv muaj cov txheej txheem tsim tshwj xeeb tshaj plaws thiab yog cov pheej yig tshaj plaws hauv qab ceramic substrates. Their exceptional qualities include high strength, high hardness, resistance to corrosion, resistance to wear, resilience to high temperatures, and superior insulating performance.

Txawm li cas los xij, lub dog alumina substrates feem ntau siv nyob rau hauv cov ntawv thov uas muaj kev ntseeg siab thiab txwv tsis pub cua sov dissipation muaj peev xwm ntawm alumina ceramics.

2. Lub cev Alm Ceramic Substrate

Vim tias nws siab thermal conductivity (theoretical thermal conductivity 319 w / (mineric nthuav tawm cov khoom siv sib xyaw ua ke hauv kev lag luam me me

Tam sim no, High-voltage thiab high-tam sim no lub zog hloov chaw, thiab DC lub zog hloov dua tshiab, High-voltage conventents ceramic submos (amb-aln) ua los ntawm cov txheej txheem AMDAN. However, the application range of AMB-AlN copper-clad substrates is limited because to their comparatively poor mechanical strength, which also affects their high and low temperature cycle impact life.

3. Chaw Soob3N4 Ceramic Substrate

Cov tuab tooj liab txheej (txog 800μm), muaj kev hloov cua sov muaj zog, thiab cov thermal cua sov (my3n4 ceramic substtrates. Tshwj xeeb, nws muaj peev xwm ntau dua los thauj cov cua sov tam sim no thiab zoo dua thaum lub tshuab raj tooj liab tawv yog welded rau qhov yooj yim bin3n4 ceramic.

Rau cov ntawv thov kom muaj kev cia siab, muaj kev tawm tsam cua sov, xws li cua tshuab hluav taws xob, thiab cua sov cov khoom siv tam sim no yog tam sim no cov khoom siv ntawm kev xaiv.