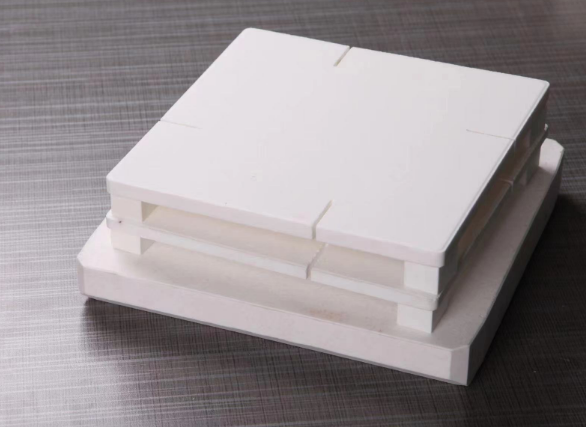

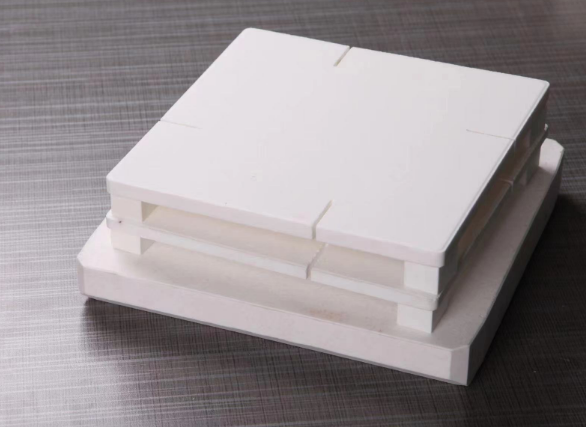

(WintrustekTsim ob qho tib siTus nasthiabTus mullite)

Alumina Ceramic, qee zaum hu uaTxhuas OCIDE (AL2O3) or tus nas, yog ib qho kev lag luam oxide ceramic uas yog heev thermally thiab ruaj khov. Vim yog lawv cov txiaj ntsig,Alumina Ceramicsyog cov neeg nyiam tshaj plaws rau kev ua kom xeb, hnav, thiab cov txheej txheem kev teeb tsa. Feem ntau ua los ntawm Bauxite, Alumina Ceramics tuaj yeem raug puab los ntawm kev nqus tawm los ntawm kev nqus tawm los ntawm kev nqus tawm los ntawm kev nqus tawm los ntawm kev nqus tawm los ntawm kev nqus tawm los ntawm extrusion, iseeftatic nias, thiab pob zeb diamond machining.

Tus mulliteyog tsim los ntawm fuser silica thiab alumina nyob rau sib xyaw sib txawv thaum lub sijhawm Sinteringing cov txheej txheem, tsim ntau cov ntaub ntawv. Rau cov khib nyiab ntom, nws yog hu ua mullite; Rau cov qib siab tseem ceeb, nws yog hu ua ntxig mullite lossis corundum.

Muaj ob hom hluavtaws mullite (al2o3-sidio2) cov khoom lag luam: porous thiab impervious cov ntawv. Lub zog siab thiab cov tshwj xeeb tsis kam rau kev poob siab kub yog sib xyaw ua ke hauv densely sintered (tsis zoo) mullite. Mob hlwb Mullite qhov tsis tshua muaj cua sov thiab muaj lub zog siab muab lub zog siab muab cov qib kev poob siab.

Mullite CeramicsUa haujlwm hauv hluav taws xob rwb thaiv tsev, cov cua sov, tso cua sov, thiab hnav thiab kev ua haujlwm kub ntxhov thiab ua haujlwm ntawm txog li 2910F (1600 ° C).

Cov cuab yeej tseem ceeb rauTus nas:

Qhov Twg

Lub zog siab thiab hardness

Kev Rwb Hluav Taws Xob

Kev tiv thaiv zoo heev thiab kev sib txhuam

Muaj peev xwm tiv thaiv corrosion ntawm kev nce kub

Cov cuab yeej tseem ceeb rauTus mullite:

Ruaj khov ntawm cov kub

Kuj mus rau Tshuaj

Tsawg heev nthuav dav ntawm tshav kub

Lub zog ntawm cov neeg kho tshuab

Rwb thaiv tsev rau cov tshuab hluav taws xob

Cov qauv thiab muaj pes tsawg leeg

Txhuas OCIDE (AL2O3)Nrog cov qib purity xws li 75% mus rau ntau tshaj 99% yog cov khoom siv tseem ceeb siv los ua alumina ceramics. Hardness thiab hnav tsis kam nrog alumin confentration. Tus qauv crystalline muab cov kav ntev thiab kev kho tshuab.

Cov khoom uas ua rauMullite Ceramicsyog txhuas silicate (3alo3·2SiO2). Lawv feem ntau yog tsim los ntawm kev kub siab rau ntawm silica thiab alumina, uas tsim ib lub teeb xim tawv nrog cov qauv zoo dua qub. Mullite lub resilience rau thermal poob siab thiab tsawg heev thermal expansion ua rau nws muaj nuj nqis heev.

Cov Khoom Siv Lub Cev

Tus nasQhov kev ua phem ua rau nws zoo tag nrho rau kev txiav cov cuab yeej thiab kev tiv thaiv tiv thaiv.

Tus mullite'S tshwj xeeb cov yam ntxwv thermal thiab lub zog (6-7 mohs hardness) ua nws qhov kev xaiv zoo rau cov dav hlau engineering thiab refractters.

Cov Khoom Siv Neeg Kho Tshuab

Tus nasyog zoo-paub rau nws cov hardness zoo tshaj plaws, siab compressive zog, thiab siab dua kev coj tsis kam tiv. Cov yam ntxwv zoo no ua nws qhov kev xaiv zoo rau kev hnav cov hnab nqa, thiab cov ntawv thov sib tsoo qhov twg yog qhov kev txhawj xeeb loj.

Tus mulliteyog qhov nyuaj dua li alumina, tsis tau nws muab kev ua tau zoo lub sijhawm thaum tseem muaj qis dua hauv qhov hnyav. Nws cov neeg kho tshuab zoo yog sib npaug los ntawm nws lub peev xwm tiv thaiv loj thiab kub hloov.

Thermal thiab Tshuaj Tshuaj Kuj

Alumina Ceramicstuaj yeem tawm tsam kev khiav hauj lwm tsis tshua muaj cua sov thaum seem kev coj ua hauv qab kev hnav hnyav hauv kev coj. Lawv kuj tiv taus cov kua qaub heev thiab alkalis, ua rau lawv zoo tag nrho rau cov kab kev ua yeeb yam sib txawv.

Tus mulliteCeramics sawv tsis tshua muaj rau lawv cov siab thermal tsis kam thiab thermal conductivity. Lawv ua haujlwm zoo rau hauv cov cua sov kub, kiln pob, thiab cov ntawv thov kev kho kom tsis txhob ua qhov twg thermal cycling tshwm sim feem ntau.

Daim Ntawv Thov:

Tus nas'S hluav taws xob insulating zoo ua rau nws haum rau hluav taws xob substrates thiab biomedical li. Vim tias lawv cov kev tshwj xeeb hnav tsis kam, Alumina Ceramics muaj feem ntau siv nyob rau hauv kev sib tsoo cov khoom sib tsoo, thiab cov kav dej uas ntev kev pabcuam lub neej.

Tus mullite'Sigh kub ruaj khov yog qhov tseem ceeb rau cov ntaub ntawv refactory thiab cov dav hlau sib xyaw.

Los xaus,Alumina CeramicsYog cov khoom xaiv rau kev hnav zoo thiab siv tshuaj ua yeeb yam vim lawv lub hardness, hnav tsis kam, thiab tshuaj lom neeg.Mullite Ceramics, ntawm qhov tod tes, muaj superior thermal stability thiab resilisence kom ceev viav vias, ua rau lawv haum rau cov ntawv thov kub siab.