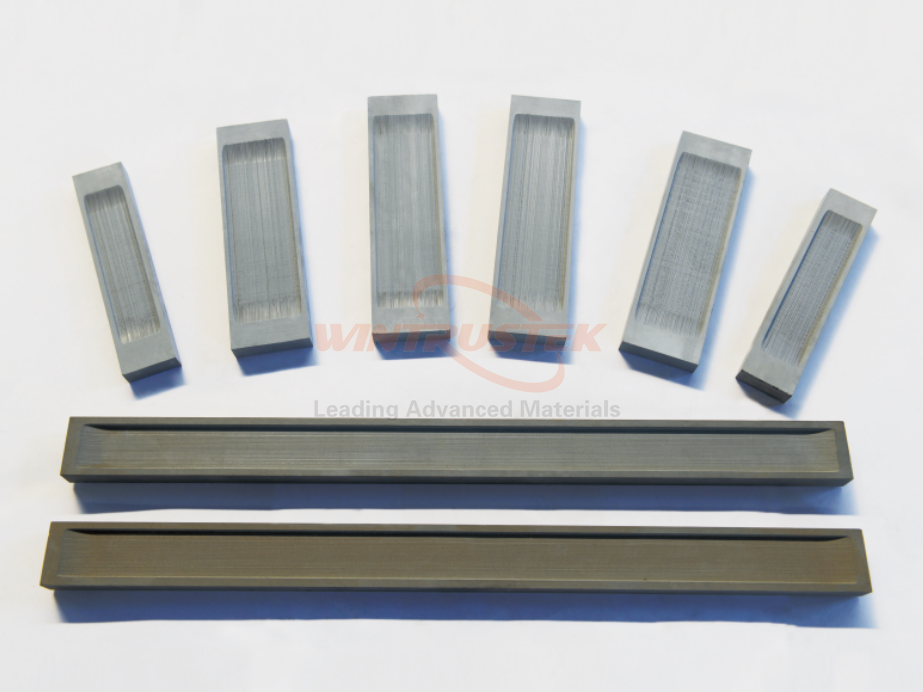

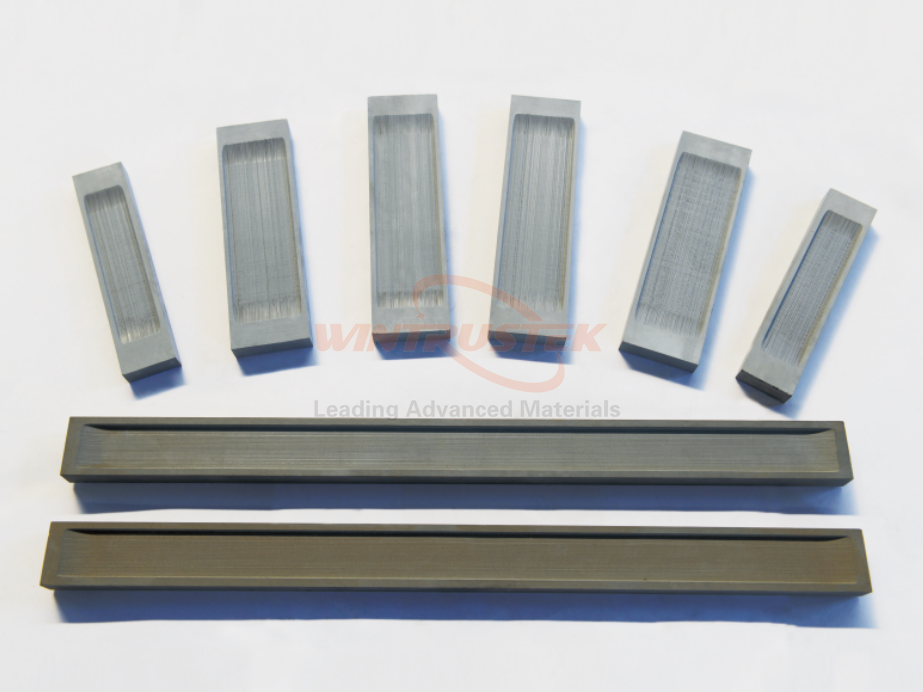

(BN-AlN-TiB2 Composite Evaporation Boat Produced by Wintrustek)

Introduction:

The BN-AlN-TiB2 Composite Evaporation Boat is a high-performance, long-lasting evaporation source core component made with innovative ceramic composite technology. It is not a single material but rather a micro-scale composite and optimal blend created through precise design. This blend comprises boron nitride (BN) for lubricity and thermal shock resistance, aluminum nitride (AlN) for high thermal conductivity and insulation, and titanium diboride (TiB2) for high electrical conductivity and wear resistance. The goal is to develop a breakthrough product that outperforms conventional single materials, such as graphite or quartz, in harsh working conditions.

Designed specifically for demanding industrial environments with high temperatures, high currents, aggressive metal melt corrosion, and rapid thermal cycling, the evaporation boat's unique material composition and sintering process allow it to maintain electrical conductivity for resistance heating while retaining the strength and stability of structural ceramics. This effectively addresses major bottlenecks in classic evaporation boats, such as cracking, distortion, metal permeation, and a limited service life.

Advantage:

Boron Nitride (BN)

Offers outstanding high-temperature lubricity while decreasing material adhesion.

A low thermal expansion coefficient increases thermal shock resistance.

High resistivity improves current distribution and prevents localized overheating.

Aluminum Nitride (AlN)

High thermal conductivity results in better thermal homogeneity.

Great insulation and high-temperature stability.

Increased mechanical strength and erosion resistance.

Titanium Diboride (TiB2)

High electrical conductivity leads to efficient Joule heating.

Ultra-high hardness and wear resistance increase service life.

Excellent oxidation resistance adapts to high-temperature oxygen conditions.

Application:

1. Vacuum Coating

Evaporation of metal films, such as aluminum, silver, and copper (photovoltaic back electrodes and optical coatings).

Metallized electrodes are prepared for semiconductor devices.

2. High-Temperature Materials Processing

3. Scientific Research and Specialized Procedures

Conclusion:

TiB2-BN-AlN composite conductive ceramic evaporation boats are widely used in the metal evaporation industry because of the benefits of the composite material, which combines the high melting point, high chemical stability, high hardness, good conductivity, and positive resistivity temperature coefficient of TiB2, the electrical insulation, molten metal corrosion resistance, excellent thermal shock resistance, and good machinability of BN, and the high insulation and thermal shock resistance of AlN.