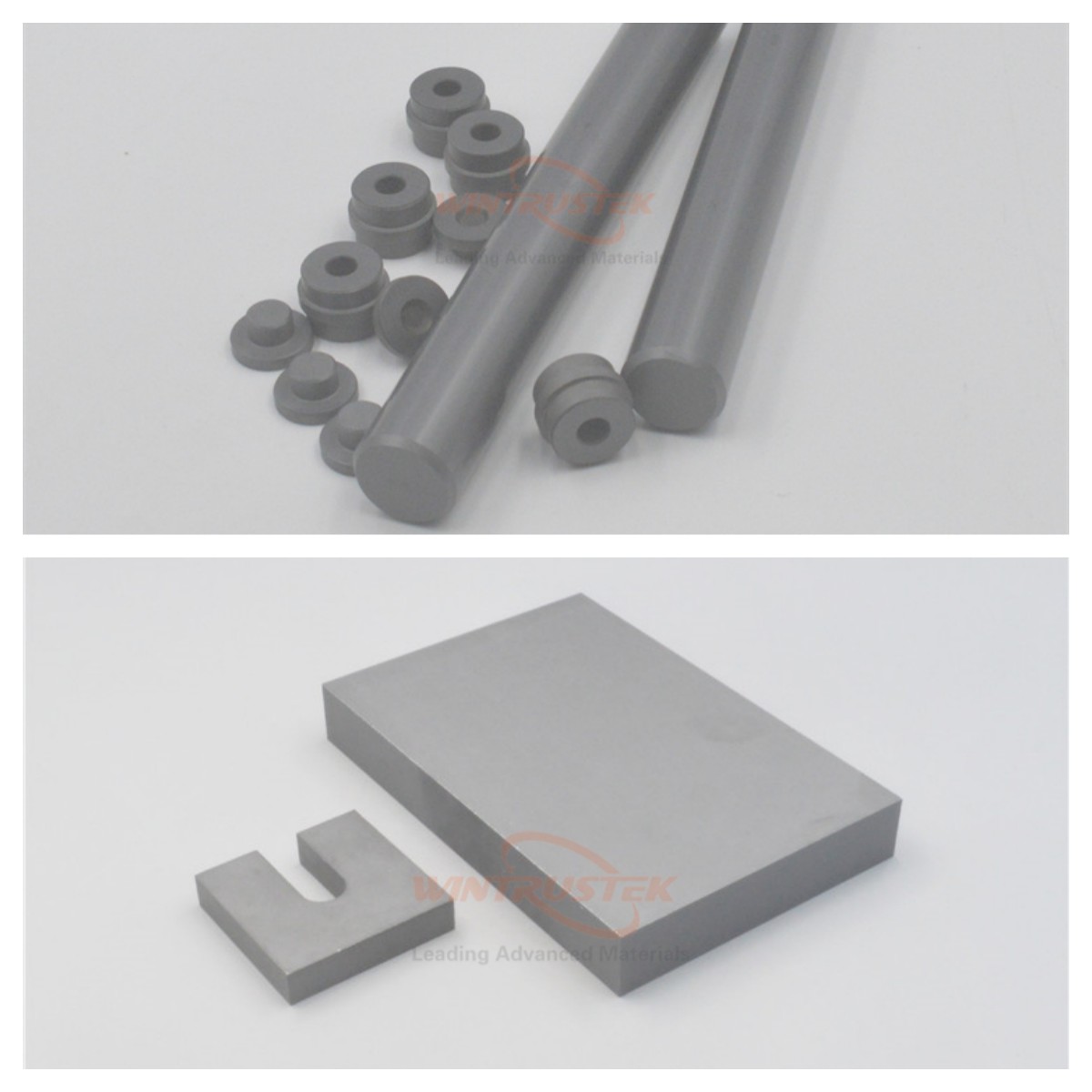

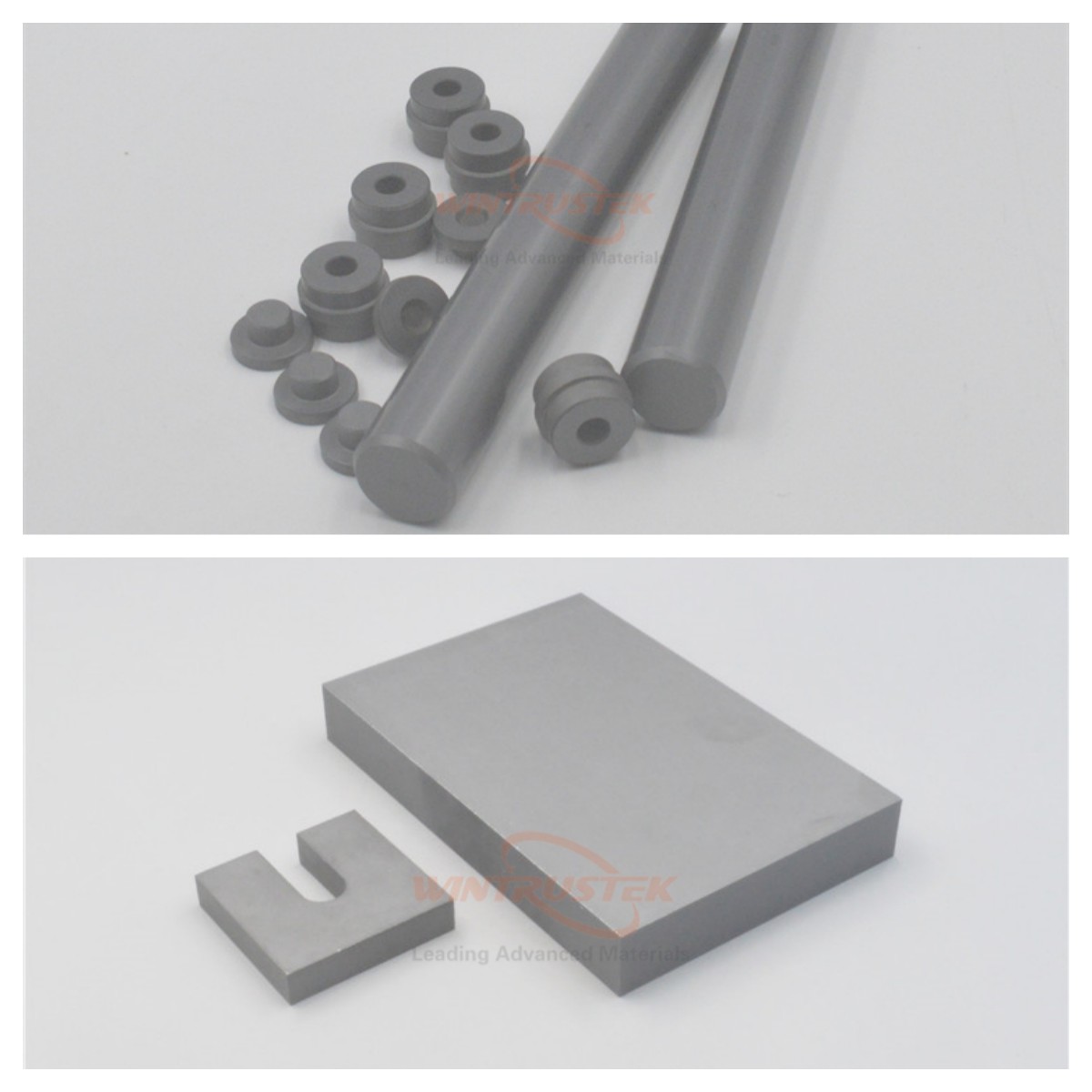

(SiricthiabB4CTsim los ntawmWintrustek)

Engineers, cov tsim qauv tsim qauv, thiab tsim kev tswj hwm yuav tsum ua qhov kev txiav txim siab tseem ceeb thaum xaiv cov khoom siv uas tsim nyog cov khoom muajeramic tsim nyog.Boron Carbide (B4C)thiabSilicon Carbide (Sic)Yog nrov kev qhia tshwj xeeb vim lawv lub siab tawv, thermal stability, thiab kuj mus rau qhov xwm txheej hnyav. Txawm li cas los xij, lawv pab cov laj thawj sib txawv-thiab xaiv qhov tsis yog tus tuaj yeem muaj kev cuam tshuam rau tus nqi, kev ua haujlwm ruaj khov, thiab kev ua haujlwm txhua yam.

Cov lus qhia ntxaws ntxaws no pivBoron carbidenrogSilicon CarbideNyob rau hauv cov nqe lus ntawm cov nta, siv, cov txiaj ntsig, thiab cov txiaj ntsig los pab koj txiav txim siab cov khoom zoo tshaj plaws rau koj qhov project tshwj xeeb.

1. Txheej txheem cej luam ntawm ob qho khoom siv

Boron Carbide (B4C)

Boron carbideyog ib qho ntawm cov ntaub ntawv uas muaj zog tshaj plaws, kev ntaus nqi tsuas yog tom qab pob zeb diamond thiab cubic boron nitride. Nws yog lub cev yuag heev, tshuaj inert, thiab nquag siv hauv kev tiv thaiv kev ua haujlwm siab thiab hnav-resistant applications.

Silicon Carbide (Sic)

Silicon Carbideyog cov paub zoo rau nws lub siab tawv, thermal conductivity, thiab zoo dua lub thermal ua poob siab tsis kam. Nws yog txoj haujlwm ua haujlwm ntawm cov kws ua haujlwm engineering thiab feem ntau tsawg dua li boron carbide.

2. Cov khoom sib piv: B4C vs.Siric

Ntiag tug

| Boron Carbide (B4C) | Silicon Carbide (Sic) |

| Ceev | Tsawg heev (~ 2.52 g /M³) | Tsawg / QUB (~ 3.1 g /M³) |

| Kev nyuaj | Siab heev (≈ 30 GPA) | Siab heev (≈ 25-28 GPA) |

| Hnav Tsis kam | Zoo tshaj | Zoo heev |

| Ntsuas Cov Pob Txheem Pob Tais | Qis dua (ntau nkig) | Siab dua (zoo dua kev poob siab tsis kam) |

| Thermal conductivity | Tswj kav | Siab heev (kev kub kub tau zoo heev) |

| Tshuaj Kuj | Pom yoojyim | Zoo tshaj |

| Ballistic Performance | Zoo tshaj | Zoo tab sis hnyav dua |

| Tus nqi | Siab dua | Muaj nqi ntau dua |

3. Thaum xaivBoron carbide

3.1 rau qhov hnyav-tseem ceeb

Boron Carbide yog ib qho ntawm cov txheej txheem huab cua zoo tshaj plaws, ua rau nws txo qhov hnyav tsis muaj teeb meem nyuaj.

3.2 Rau kev tiv thaiv qib siab

B4Cyog qhov kev xaiv zoo tshaj plaws rau:

Nws cov kev tsis sib xws nyuaj ua rau nws los thaiv cov kev sib tw siab uas muaj qhov hnyav tsawg.

3.3 Rau qhov muaj ib puag ncig dhau ib puag ncig

Boron carbideTxawj Ntse ntawm:

Nws cov kev coj tsis taus feem ntau cov txiaj ntsig hauv lub neej ntev dua li sic hauv qhov xwm txheej phem tshaj plaws.

4. Thaum xaivSilicon Carbide

4.1 rau siab thermal conductivity apps

Silicon Carbideyog tsim nyog rau:

Nws maj nrawm dispipates kub thiab tuaj yeem tiv thaiv huab kub hnyav tsis muaj kev tawg.

4.2 rau cov phiaj xwm kev lag luam rhiab

Siricyog nrov vim nws muab kev ua tau zoo ntawm tus nqi qis dua:

4.3 rau cov xwm txheej yuav tsum muaj kev nruj dua

Sic yog tsawg dua li nkev tshaj b₄c, ua rau nws ruaj khov rau kev cuam tshuam, kev co, thiab thermal cycling.

5. Tus nqi sib piv

Thaum lub sij hawm tiag tiag tus nqi nyob ntawm purity, loj, thiab cov txheej txheem tsim khoom:

Boron carbideyog ntaukim kim dua vim cov khoom siv raw thiab sophisting sintering.

Silicon carbide muaj nqi ntau dua, tshwj xeeb rau cov khoom loj lossis cov khoom lag luam loj.

B₄C yog qhov kev xaiv zoo tshaj plaws rau kev ua tiav qhov siab tshaj plaws ntawm ib tus nqi.

Yog tias qhov kev ua tau zoo-rau-tus nqi sib piv yog qhov tseem ceeb, sic feem ntau yog qhov kev xaiv zoo.

6. Kev lag luam uas tau txais txiaj ntsig los ntawm txhua cov khoom

Boron carbide

Silicon Carbide

7. Cov khoom siv twg koj yuav xaiv?

XaivBoron carbideYog tias koj daim ntawv thov xav tau

Qhov Zoo Tshaj Plaws

Hnyav tshaj plaws ua tau ceeb thawj

Tau ua dawb huv heev kuj

Kev ua haujlwm zoo tshaj plaws

Corrosion tsis kam nyob rau hauv loj teeb tsa

XaivSilicon CarbideYog tias koj daim ntawv thov xav tau

Cov nqi qis dua cov nqi

Siab siab thermal conductivity

Txhim Kho Cov Khoom Siv Hluav Taws Xob

Kuj mus rau Bermal Poob Siab

Loj loj lossis nyuaj ua ntu

8. Conclusion

Ob lub boron carbide thiab silicon carbide yog cov siab-ua haujlwm tau zoo tshaj ceramics, tseem lawv tau txais kev sib tw hauv thaj chaw sib txawv.

Boron CarbidE yog unparalleled nyob rau hauv hardness, qhov hnyav txo, thiab kev ua tau zoo, ua rau nws zoo heev rau kev ua rog thiab cov chaw siab.

Silicon CarbideMuaj cov khoom siv ua kom zoo nkauj stability, kev ua tau zoo, thiab tus nqi-ua tau zoo, ua rau nws cov khoom siv zoo rau kev lag luam thiab ntsuas kub-kub.

Cov ceramic zoo tshaj plaws rau koj daim ntawv thov tau txiav txim siab los ntawm nws cov kev xav tau tshwj xeeb. Rau ntau daim ntawv thov, ntsuas qhov hnyav, thermal tus cwj pwm, kev coj nruj, thiab nyiaj txiag yog qhov tseem ceeb los xaiv cov khoom siv zoo tshaj plaws.