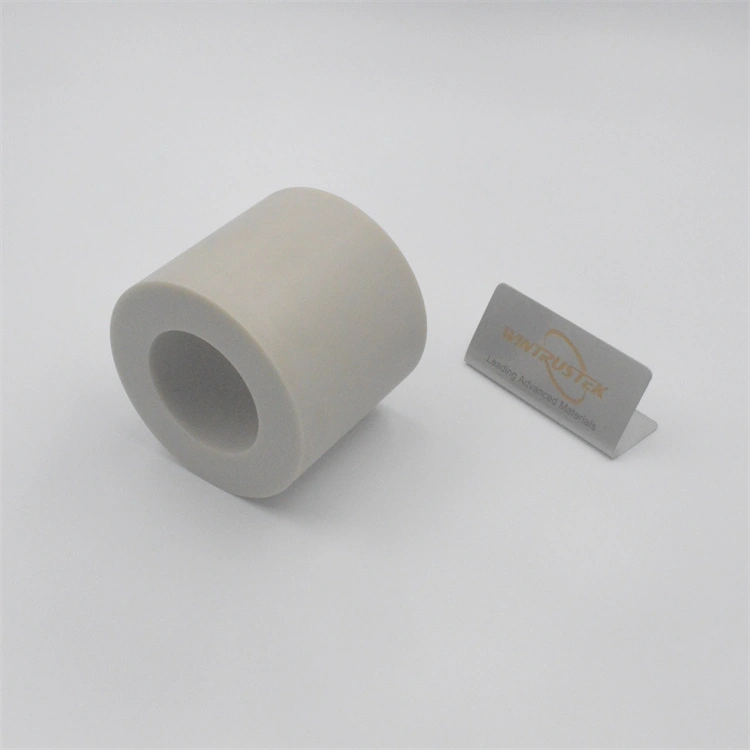

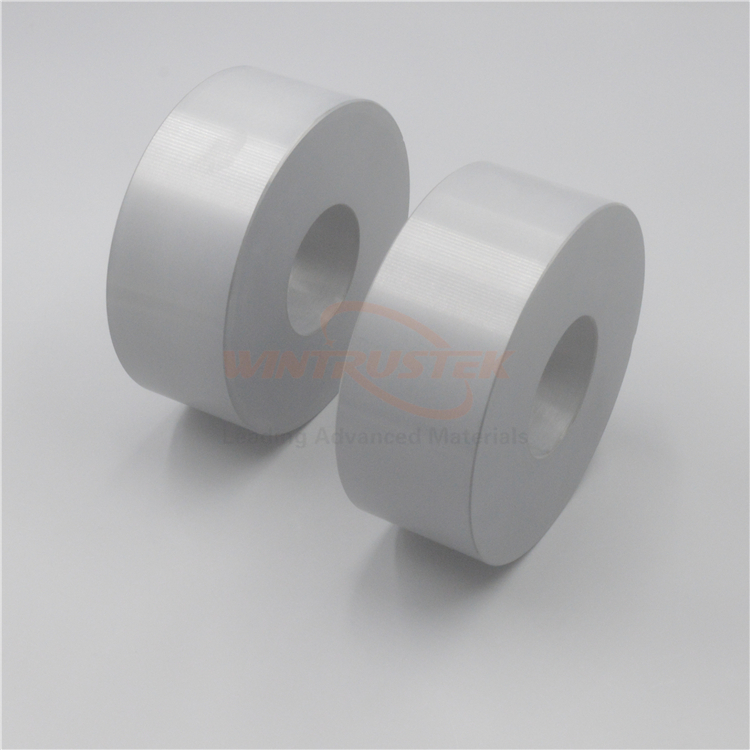

Boron Nitride (BN) Ceramics Made By WINTRUSTEK

Boron Nitride (BN) ceramics are among the most effective technical-grade ceramics. They combine exceptional temperature-resistant properties, such as high thermal conductivities, with high dielectric strength and exceptional chemical inertness to solve problems in some of the world's most demanding application areas.

Boron Nitride ceramics are manufactured by pressing at high temperatures. This method employs temperatures as high as 2000°C and moderate to substantial pressures to induce the sintering of raw BN powders into a large, compact block known as a billet. These Boron Nitride billets can be effortlessly machined and finished into smooth, complex-geometry components. Easy machinability without the hassle of green firing, grinding, and glazing allows for rapid prototyping, design modifications, and qualification cycles in a variety of advanced engineering applications.

Plasma chamber engineering is one such use of Boron Nitride ceramics. BN's resistance to sputtering and low propensity for secondary ion generation, even in the presence of strong electromagnetic fields, distinguish it from other advanced ceramics in plasma environments. Resistance to sputtering contributes to the durability of components, while low secondary ion generation helps preserve the plasma environment's integrity. It has been used as an advanced insulator in a variety of thin-film coating processes, including plasma-enhanced physical vapor deposition (PVD).

Physical vapor deposition is a term for a wide range of thin-film coating techniques that are done in a vacuum and are used to change the surface of different materials. People often use sputtering deposition and PVD coating to make and put target material on the surface of a substrate when making optoelectronic devices, precise automotive and aerospace parts, and other things. Sputtering is a unique process in which plasma is used to keep hitting a target material and force particles out of it. Boron Nitride ceramics are commonly used to confine plasma arcs in sputtering chambers onto the target material and to prevent erosion of integral chamber components.

Boron Nitride ceramics have also been used to make satellite Hall-effect thrusters work better and last longer.

Hall effect thrusters move satellites in orbit and probes in deep space with the help of plasma. This plasma is made when a high-performance ceramic channel is used to ionize propellant gas as it moves through a strong radial magnetic field. An electrical field is used to speed up the plasma and move it through a discharge channel. The plasma could leave the channel at speeds in the tens of thousands of miles per hour. Plasma erosion tends to break down ceramic discharge channels too quickly, which is a problem for this advanced technology. Boron Nitride ceramics have been successfully utilized to increase the lifetimes of hall-effect plasma thrusters without compromising their ionization efficiency or propulsion capabilities.