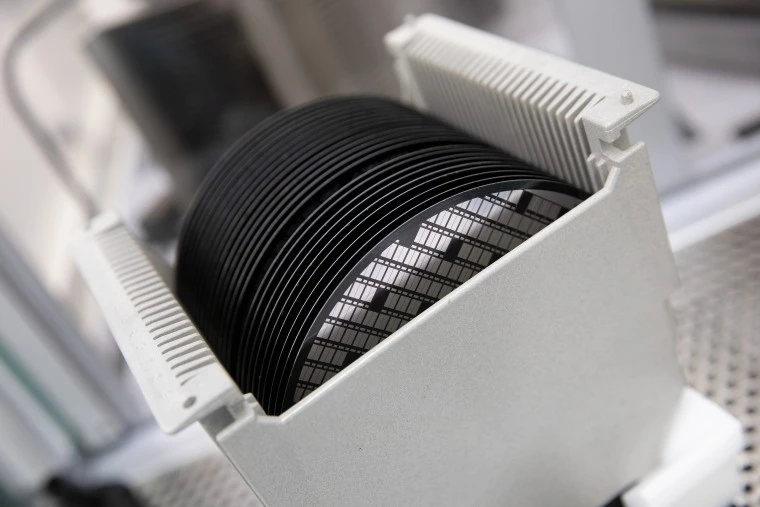

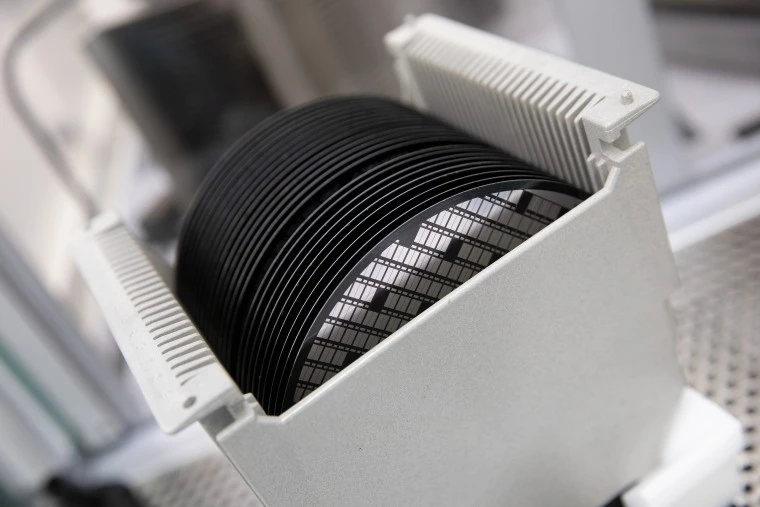

Silicon carbide (SiC) is a ceramic material that is frequently grown as a single crystal for semiconductor applications. Due to its inherent material properties and single-crystal growth, it is one of the most durable semiconductor materials on the market. This durability extends far beyond its electrical functionality.

Physical Durability

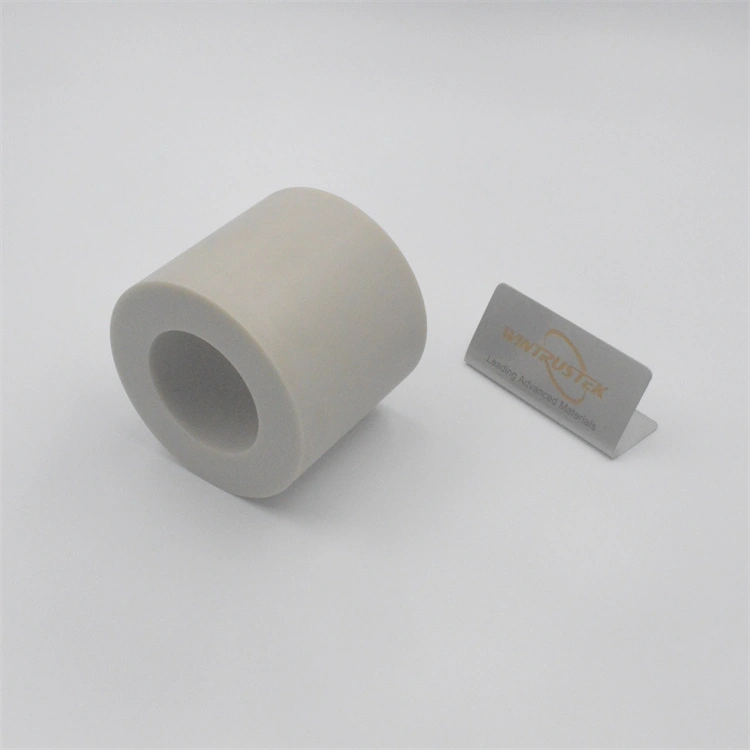

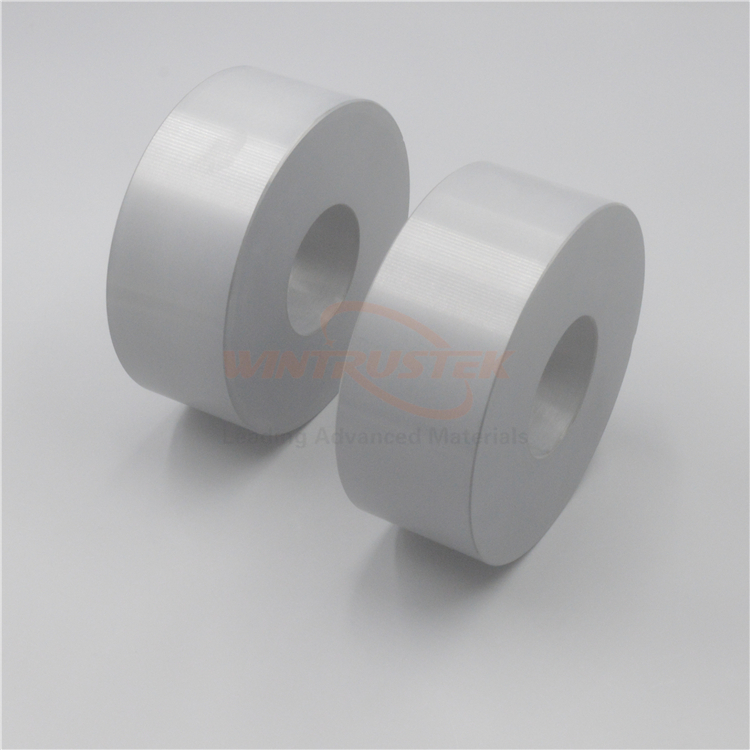

SiC's physical durability is best illustrated by examining its non-electronic applications: sandpaper, extrusion dies, bulletproof vest plates, high-performance brake disks, and flame igniters. SiC will scratch an object as opposed to being scratched itself. When used in high-performance brake disks, their resistance to long-term wear in harsh environments is put to the test. For use as a bulletproof vest plate, SiC must possess both high physical and impact strength.

Chemical and Electrical Durability

SiC is renowned for its chemical inertness; it is unaffected by even the most aggressive chemicals, such as alkalis and molten salts, even when exposed to temperatures as high as 800 °C. Due to its resistance to chemical attack, SiC is non-corrosive and can withstand harsh environments including exposure to humid air, salt water, and a variety of chemicals.

As a result of its high energy bandgap, SiC is highly resistant to electromagnetic disturbances and the destructive effects of radiation. SiC is also more resistant to damage at higher levels of power than Si.

Thermal Shock Resistance

SiC's resistance to thermal shock is another important characteristic. When an object is exposed to an extreme temperature gradient, thermal shock occurs (i.e., when different sections of an object are at significantly different temperatures). As a result of this temperature gradient, the rate of expansion or contraction will vary between the various sections. Thermal shock can cause fractures in brittle materials, but SiC is highly resistant to these effects. The thermal shock resistance of SiC is a result of its high thermal conductivity (350 W/m/K for a single crystal) and low thermal expansion in comparison to the vast majority of semiconductor materials.

SiC electronics (e.g., MOSFETs and Schottky diodes) are used in applications with aggressive environments, such as HEVs and EVs, because of their durability. It is an excellent material for use in semiconductor applications requiring toughness and dependability due to its physical, chemical, and electrical resilience.