Macor Machinable Glass Ceramic (MGC) performs like an advanced technical ceramic while having the versatility of a high-performance polymer and the machinability of a metal. It is a unique blend of characteristics from both families of materials and it is a hybrid glass-ceramic. In high temperature, vacuum, and corrosive situations, Macor performs well as an electrical and thermal insulator.

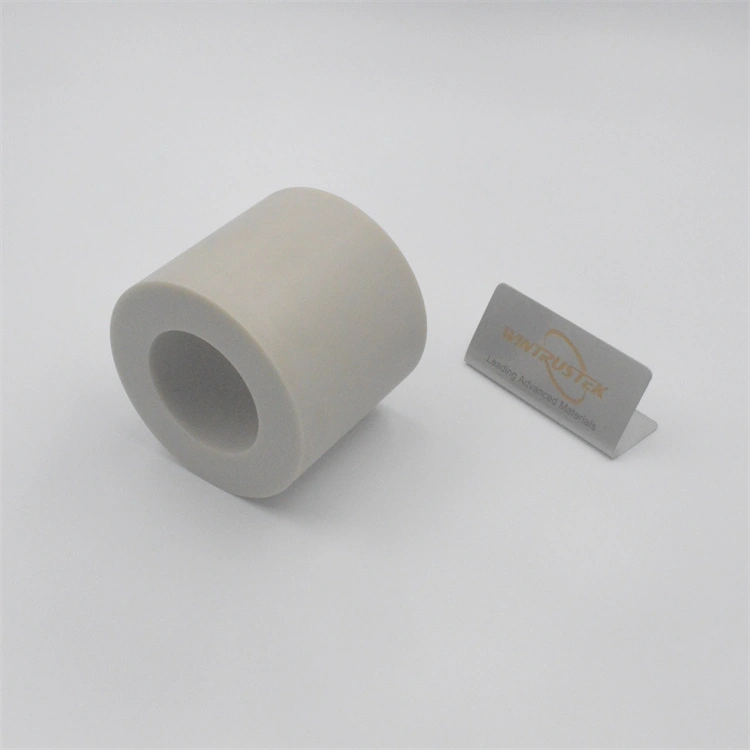

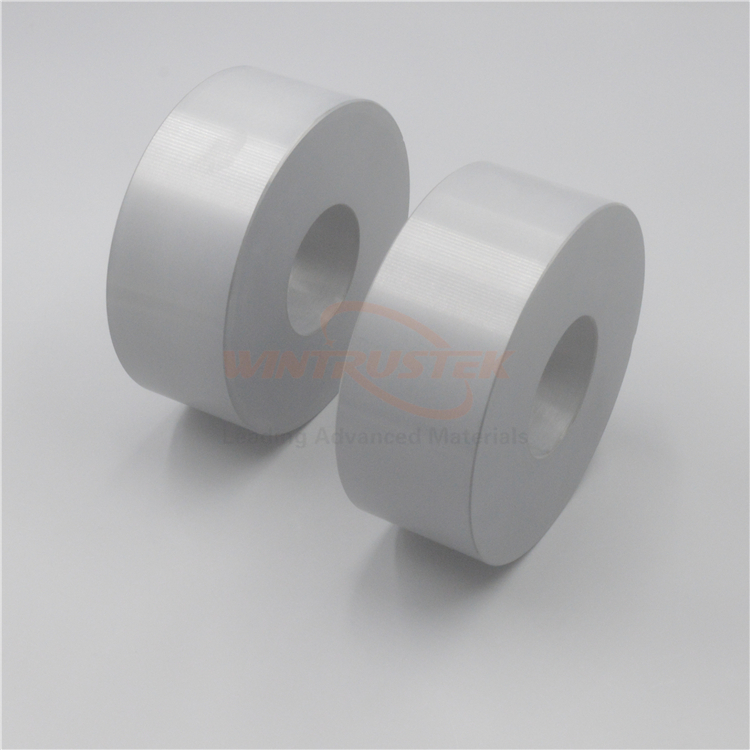

The fact that Macor can be machined using common metalworking tools is one of its key benefits. When compared to other technical ceramics, this enables noticeably quicker turnaround times and significantly reduced production costs, making it a superb material for both prototype and medium-volume production runs.

Macor has no pores and won't outgas when baked out properly. Unlike high temperature polymers, it is tough and rigid and won't creep or deform. Radiation resistance also applies to Macor machinable glass ceramic.

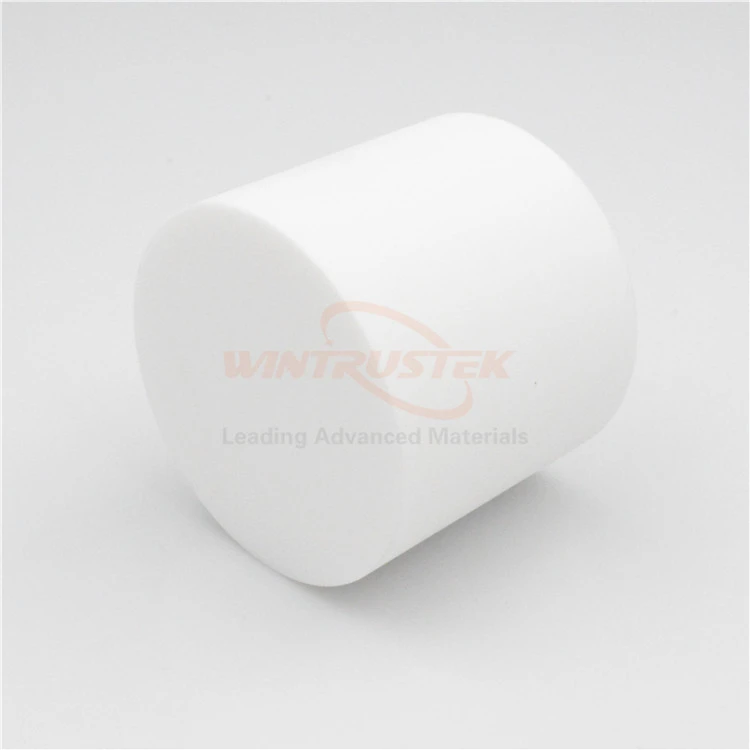

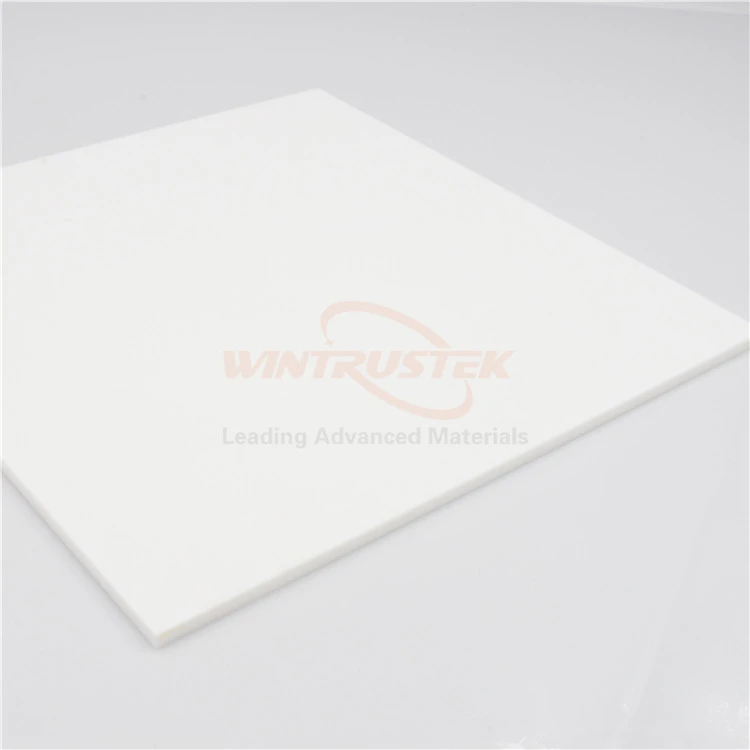

According to your specifications, we provide Macor Rods, Macor Sheets, and Macor Components.

Typical Properties

Zero porosity

Low thermal conductivity

Very tight machining tolerances

Outstanding dimensional stability

Excellent electric insulator for high voltages

Won't cause outgassing in vacuum environment

Can be machined using common metalworking tools

Typical Applications

Coil supports

Laser cavity components

High-intensity lamp reflectors

High-voltage electrical insulators

Electrical spacers in vacuum systems

Thermal insulators in heated or cooled assemblies