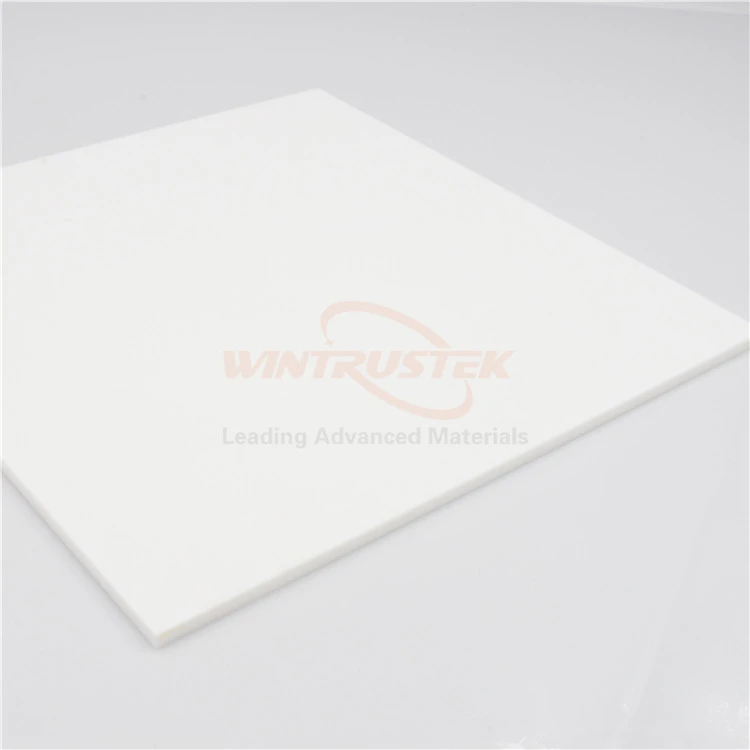

Material Overview

Macor Machinable Glass Ceramic (MGC) performs like an advanced technical ceramic while having the versatility of a high performance polymer and the machinability of a metal. It is a unique blend of characteristics from both families of materials and it is a hybrid glass-ceramic. In high temperature, vacuum, and corrosive situations, Macor performs well as an electrical and thermal insulator.

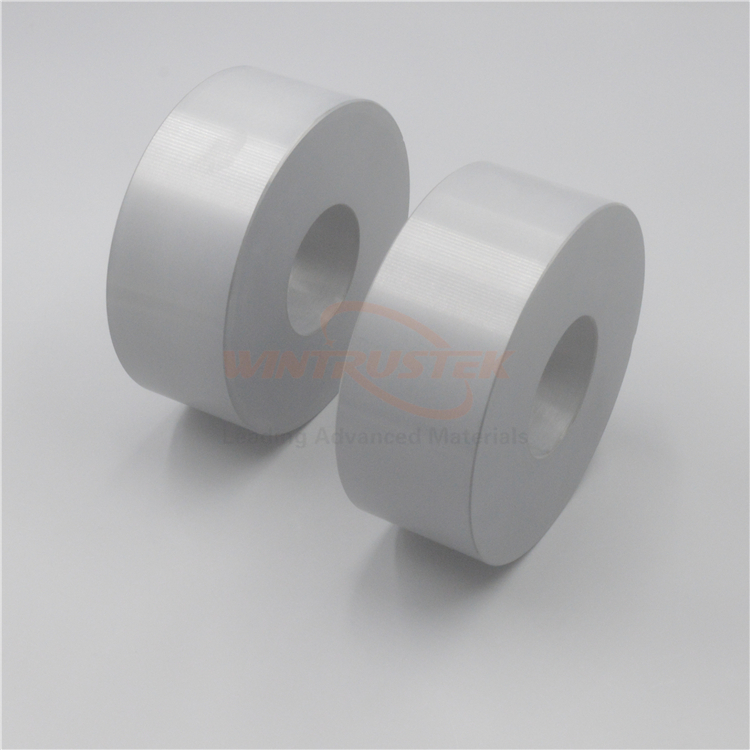

The fact that Macor can be machined using common metalworking tools is one of its key benefits. When compared to other technical ceramics, this enables noticeably quicker turnaround times and significantly reduced production costs, making it a superb material for both prototype and medium-volume production runs.

Typical Features

Can be machined using standard metalworking equipment.

Low thermal conductivity

Excellent electric insulator for high voltages

The continuous working temperature of 800 C and a peak temperature of 1000 C

Zero porosity

Won't cause outgassing in a vacuum environment

Very tight machining tolerances

Outstanding dimensional stability

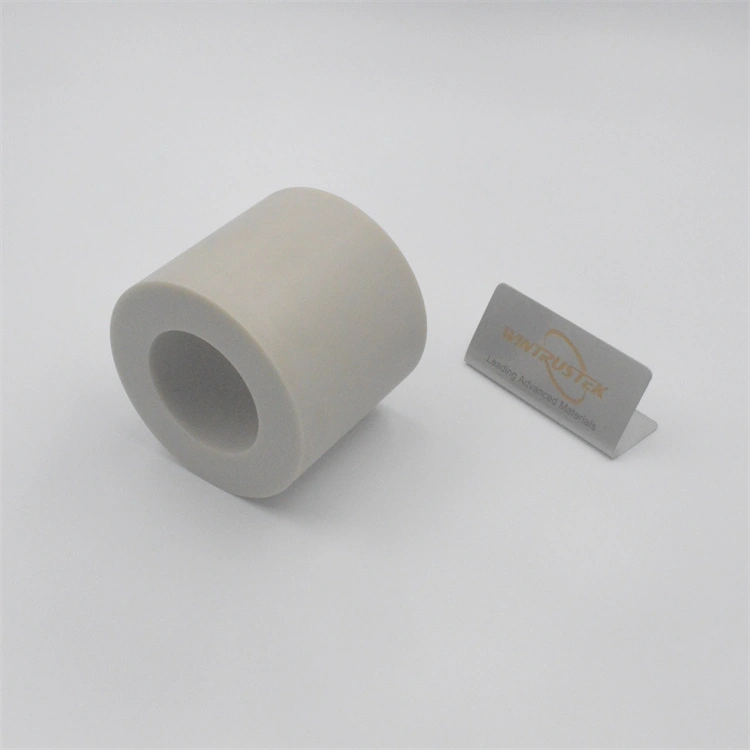

Applications

Electrical spacers in vacuum systems

Thermal insulators in heated or cooled assemblies

High intensity lamp reflectors

Laser cavity components

Coil supports

High voltage electrical insulators

Medical machinery

Wintrustek Advanced Materials is a leading ceramic materials supplier. We provide high-quality Macor Machinable Glass Ceramics at a competitive price.

More Materials

Our Advanced Ceramics include:

Alumina (Al2O3) Ceramics

Zirconia (ZrO2) Ceramics

Beryllia (BeO) Ceramics

Aluminum Nitride (AlN) Ceramics

Silicon Nitride (Si3N4) Ceramics

Hot Pressed Boron Nitride (HBN) Ceramics

Pyrolytic Boron Nitride (PBN) Ceramics

Silicon Carbide (SiC) Ceramics

Boron Carbide (B4C) Ceramics

Titanium Diboride (TiB2) Ceramics

Cerium Hexaboride (CeB6) Ceramics

Lanthanum Hexaboride (LaB6) Ceramics

Macor Machinable Glass Ceramics

Customized and complex ceramic parts are available on request.

Packaging & Shipping

Xiamen Wintrustek Advanced Materials Co., Ltd.

ADDRESS:No.987 Huli Hi-Tech Park, Xiamen, China 361009

Phone:0086 13656035645

Tel:0086-592-5716890

SALES

Email:sales@wintrustek.com

Whatsapp/Wechat:0086 13656035645