With a CAGR of 6.1%, the market for thin film ceramic substrates is predicted to increase from USD 2.2 billion in 2021 to USD 3.5 billion in 2030. The demand for high-speed data transmission is on the rise, and the price per bit for electronic devices is falling, which are two reasons that are propelling the expansion of the thin-film ceramic substrates market globally.

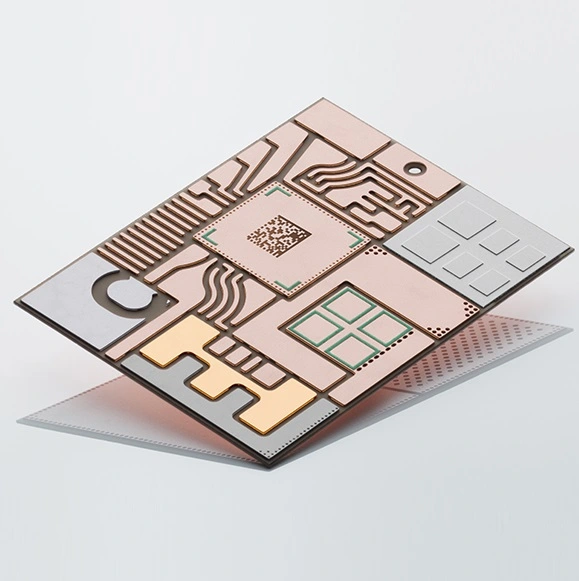

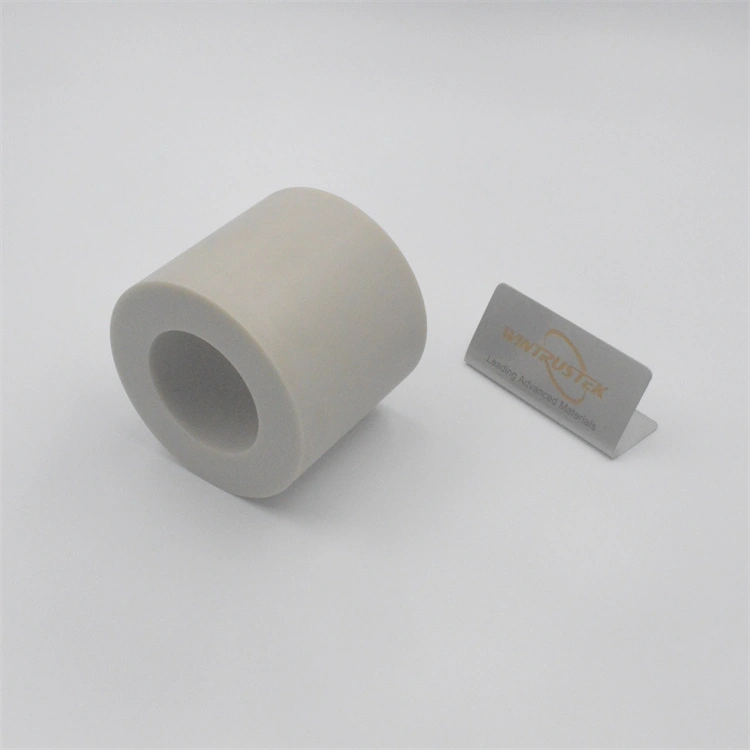

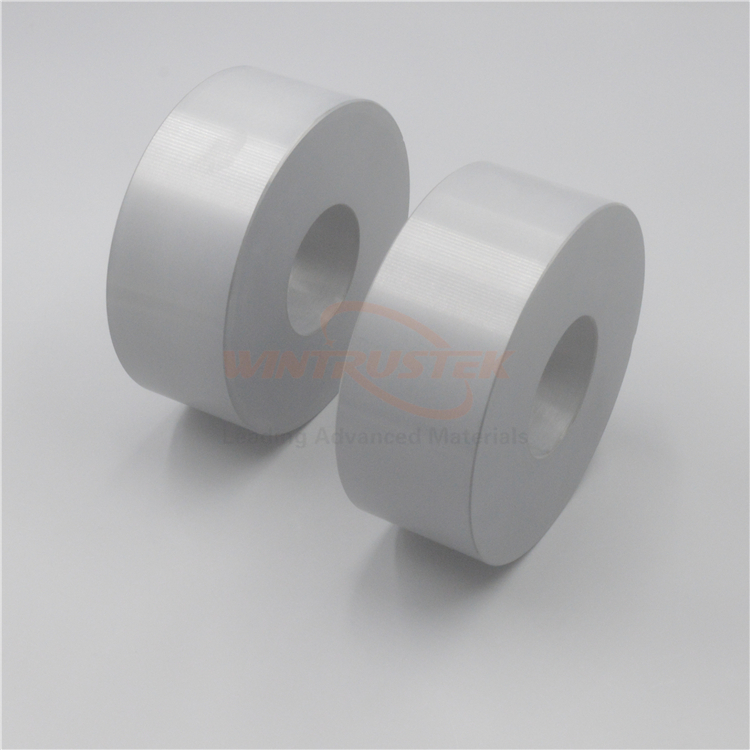

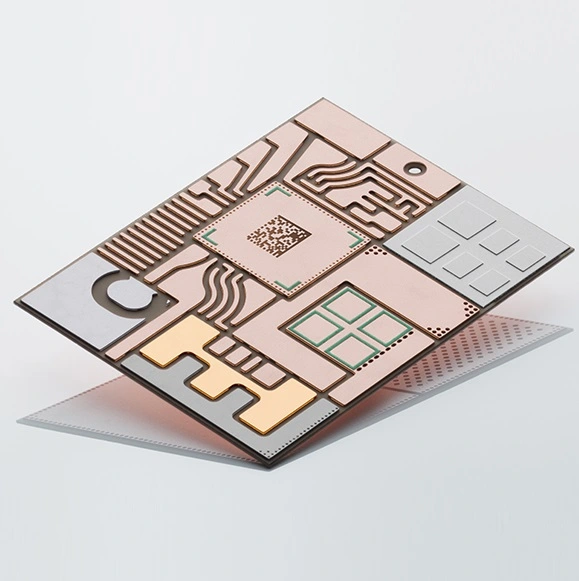

Substrates made of thin-film ceramic are also referred to as semiconductor materials. It is made up of a number of thin layers that have been built up utilizing vacuum coating, deposition, or sputtering methods. Glass sheets with a thickness of less than one millimeter that is two-dimensional (flat) or three-dimensional are considered thin-film ceramic substrates. They can be manufactured from a variety of materials, including Silicon Nitride, Aluminum Nitride, Beryllium Oxide, and Alumina. Because of thin-film ceramics' ability to transfer heat, electronics can use them as heat sinks.

The market is divided into Alumina, Aluminum Nitride, Beryllium Oxide, and Silicon Nitride categories based on type.

Alumina

Aluminum Oxide, or Al2O3, is another name for Alumina. It may be used to make ceramics that are robust but lightweight because of their intricate crystal structure. Although the material does not naturally conduct heat well, it performs admirably in environments where the temperature must be maintained consistently throughout the apparatus. Because it contributes to superior insulation properties without adding any weight to the finished product, this kind of ceramic substrate is frequently utilized in electrical applications.

Aluminum Nitride (AlN)

AlN is another name for Aluminum Nitride, and thanks to its excellent thermal conductivity, it can handle heat better than other ceramic substrates. AlN and Beryllium Oxide are ideal choices for electrical applications in settings where many electronic components are being worked on simultaneously because they can endure greater temperatures without degrading.

Beryllium Oxide(BeO)

A ceramic substrate with exceptional thermal conductivity is Beryllium Oxide. It is a great option for handling electrical applications in settings where several electronic devices are being worked on at once since it can endure high temperatures without degrading like AlN and Silicon Nitride.

Silicon Nitride (Si3N4)

Another type of material used to create thin-film ceramic substrates is Silicon Nitride (Si3N4). Unlike Alumina or Silicon Carbide, which often contain boron or aluminum, it has relatively low thermal expansion characteristics. Because they have better printing capabilities than other varieties, this type of substrate is preferred by many producers because the quality of their products is, as a result, significantly higher.

Based on where they are used, the market is split into electrical applications, the automotive industry, and wireless communications.

Electrical Application

As thin-film ceramic substrates are effective at transporting heat, they can be employed in electrical applications.

Without adding any weight to the finished product, they may control the heat and aid in greater insulation. Thin-film ceramic substrates are used in electrical applications such as LED displays, printed circuit boards (PCB), lasers, LED drivers, semiconductor devices, and more.

Automotive Application

Because they can sustain higher temperatures without degrading like Alumina, thin-film ceramic substrates can also be used in the automotive industry. This makes them ideal for electrical applications, such as in an engine compartment or dashboard, where numerous electronic devices are being worked on simultaneously.

Wireless Communications

Thin-film ceramic substrates are great for printing and can also be used in wireless communications because they don't expand or contract much when heated or cooled. This means that manufacturers can use this type of substrate to make better products.

Thin Film Ceramic Substrates Market Growth Factors

Due to the rising need for thin-film substrates across a range of end-use industries, including electrical, automotive, and wireless communications, the market for thin-film ceramic substrates is expanding rapidly. Globally growing fuel costs have a significant impact on the cost of manufacturing automobiles, increasing the cost of their production. As a result, many manufacturers have begun to use ceramic substrates, which offer exceptional thermal qualities, to enhance thermal management systems and lower engine temperature, resulting in a 20% reduction in fuel usage and emissions. As a result, these materials are now being used by the automobile sector at a higher pace, which will fuel the market's expansion even more.