Ceramic balls offer outstanding performance characteristics for applications exposed to severe chemicals or situations with extremely high temperatures. In applications like chemical pumps and drill rods, where traditional materials fail, ceramic balls offer prolonged life, decreased wear, and maybe acceptable performance.

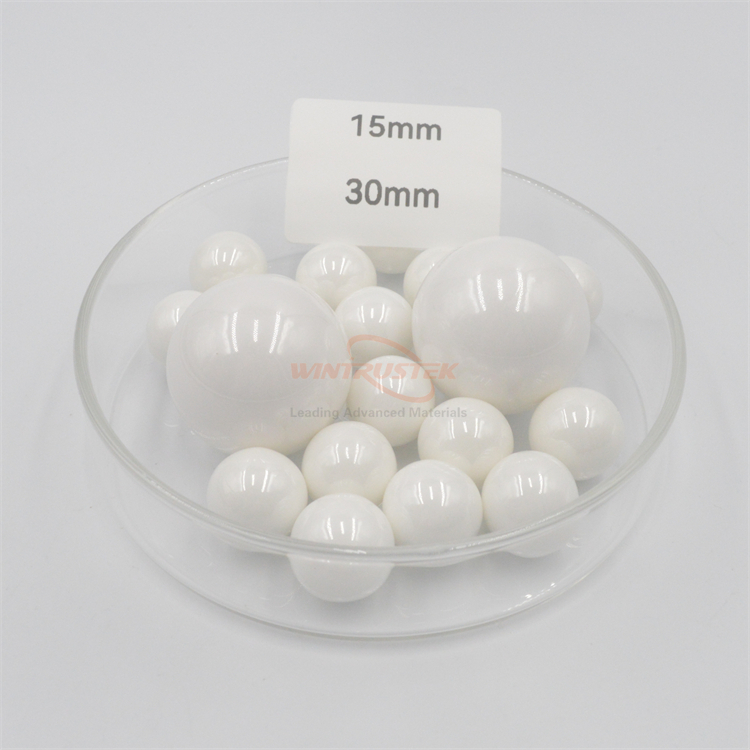

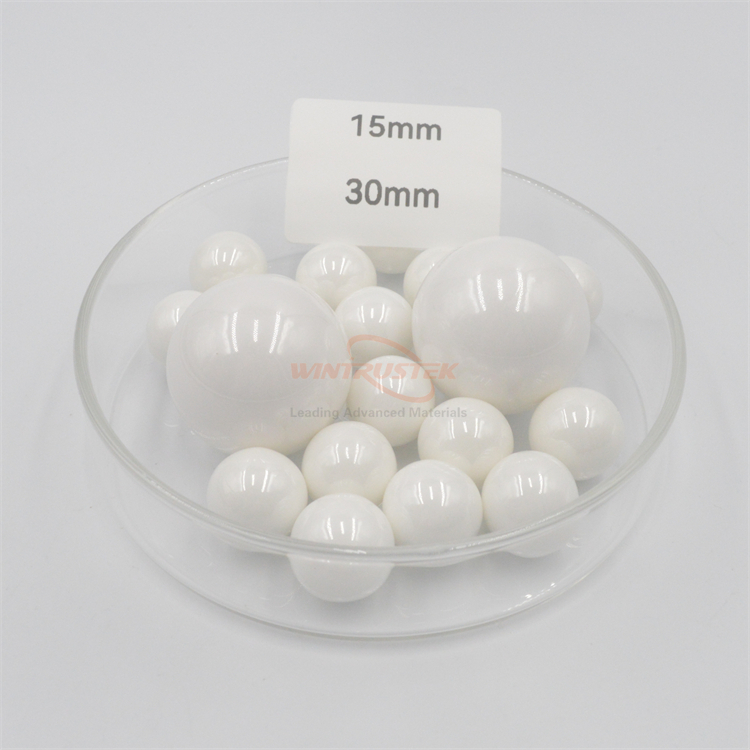

Alumina Ceramic Balls

Due to its superior corrosion resistance and high operating temperature characteristics, alumina oxide (AL2O3) is a popular choice for ceramic balls. Processing equipment uses alumina oxide balls to enhance bearing performance. Compared to their steel counterparts, alumina oxide balls are more lightweight, stiffer, smoother, tougher, corrosion-resistant, require less lubrication, and have a lower thermal expansion, allowing the bearing to operate at greater speeds and operational temperatures with less torque. Alumina ceramic balls are widely utilized in the petroleum, chemical, fertilizer, natural gas, and environmental protection industries as catalysts in reactor covering support material and tower packing.

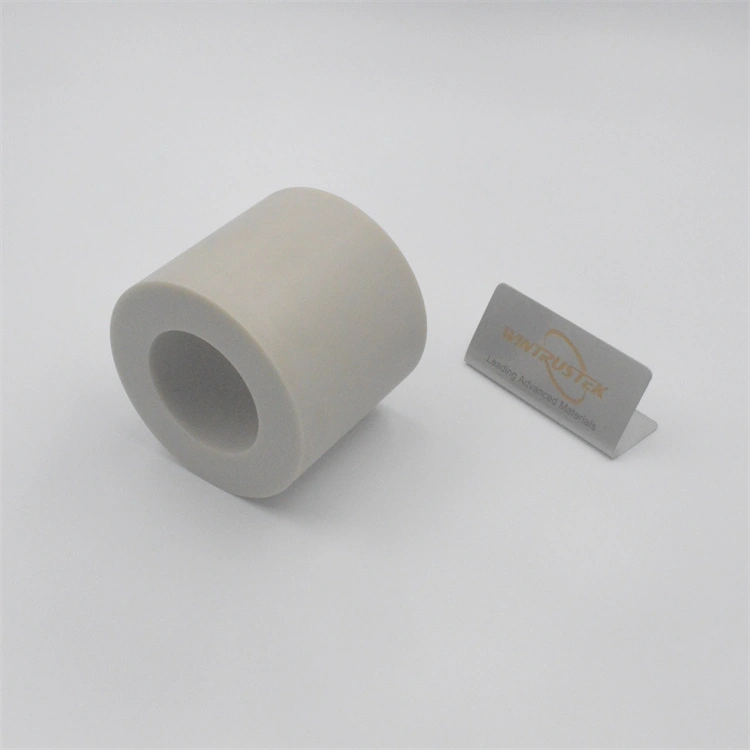

Zirconia Ceramic Balls

It is a strong substance that works effectively at temperatures as high as 1000°F (538°C) and operates effectively in conditions including molten metals, organic solvents, caustics, and the majority of acids. It is frequently used as a check valve for flow control because of its excellent resistance to abrasion and corrosion.

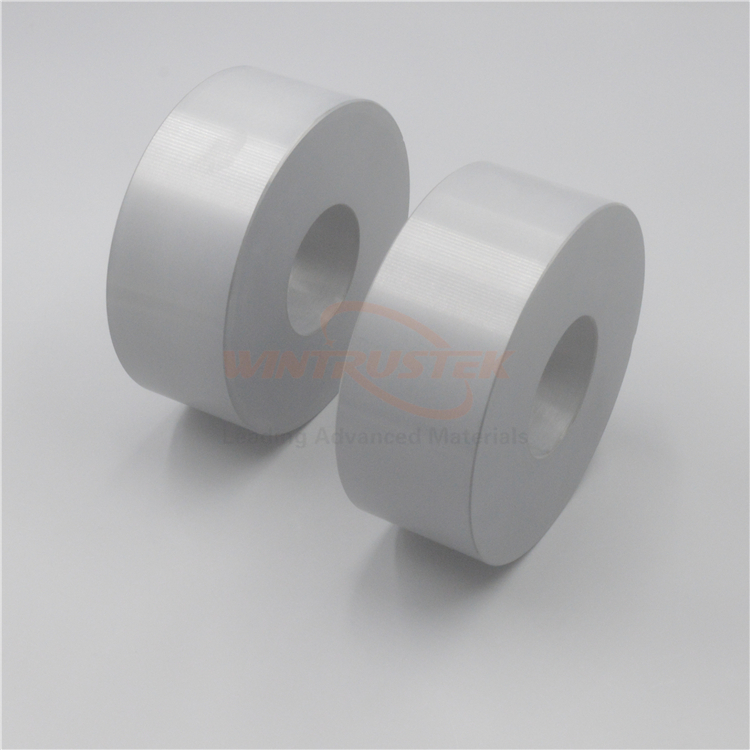

Silicon Nitride Ceramic Balls

Ceramic balls made of silicon nitride (Si3N4) are frequently used in bearings because of their strong heat resistance and low friction. They are also frequently utilized in fields including metalworking tools, gas turbines, automotive engine parts, full ceramic bearings, military and defense, and aerospace.

In applications requiring super high-speed rotation, full ceramic and hybrid ceramic bearings use silicon nitride balls. Silicon nitride has a density that is less than half that of steel, reducing centrifugal force during bearing rotation, which allows for higher working speeds.

They are electrically non-conductive and suitable for applications like electric motor shaft bearings for AC and DC motors and generators. Silicon nitride ball bearings are quickly becoming the industry standard in the production of electric motors for electric and driverless vehicles.

Silicon nitride's non-magnetic quality makes it the perfect material for use in applications that must withstand a magnetic field. The magnetic field or the spinning torque may be disturbed if steel balls are used in certain applications. Where magnetic fields are present, silicon nitride ball bearings are best suited for use in semiconductor manufacturing equipment and medical diagnostic equipment.